LA SOLUTION D’ANALYSE D’IMAGES

LA PLUS AVANCÉE

Clemex Vision est un système entièrement intégré destiné aux laboratoires recherchant des résultats traçables, reproductibles et précis. Il s’agit de notre système d’analyse d’image automatisée le plus puissant. Il comprend une large gamme de fonctions de vision artificielle, adaptées à diverses applications dans l’industrie et la recherche. Notre logiciel d’analyse d’image est exceptionnellement flexible, ce qui permet d’exécuter un nombre illimité de routines distinctes sur le même système. Ces routines sont fournies sous forme de bibliothèque d’applications existantes ou peuvent être développées par nos spécialistes en applications.

TROUSSES D’APPLICATION

TYPES D’ANALYSE

NORMES

- ASME B46.1

État de surface (Rugosité, ondulation, et épaisseur) - ASTM A247

Microstructure du graphite dans les pièces en fonte - ASTM B487

Mesure du métal et de l’épaisseur du revêtement d’oxyde - ASTM E1077

Profondeur de décarburation des échantillons d’acier - ASTME112

Taille moyenne des grains

- ASTME1245

Teneur en inclusions ou en constituant de seconde phase de métaux - ASTM E1268

Degré de lignage ou d’orientation des microstructures - ASTM E562

Déterminer la fraction du volume à l’aide du comptage manuel de point systématique - DIN

Aciers pour roulements à billes - ISO 945

Microstructure de la fonte

PRINCIPALES CARACTÉRISTIQUES DU LOGICIEL D’ANALYSE CLEMEX VISION

Universal Grain size analysis

With the AI Plugin “GrainSeg”, segmenting even the most difficult images is fast and reliable. You can analyze copper alloys, austenitic steels or titanium alloys containing twins and it supports all methods of the ASTM-E112 standard.

PERSONNALISER VOTRE ANALYSE

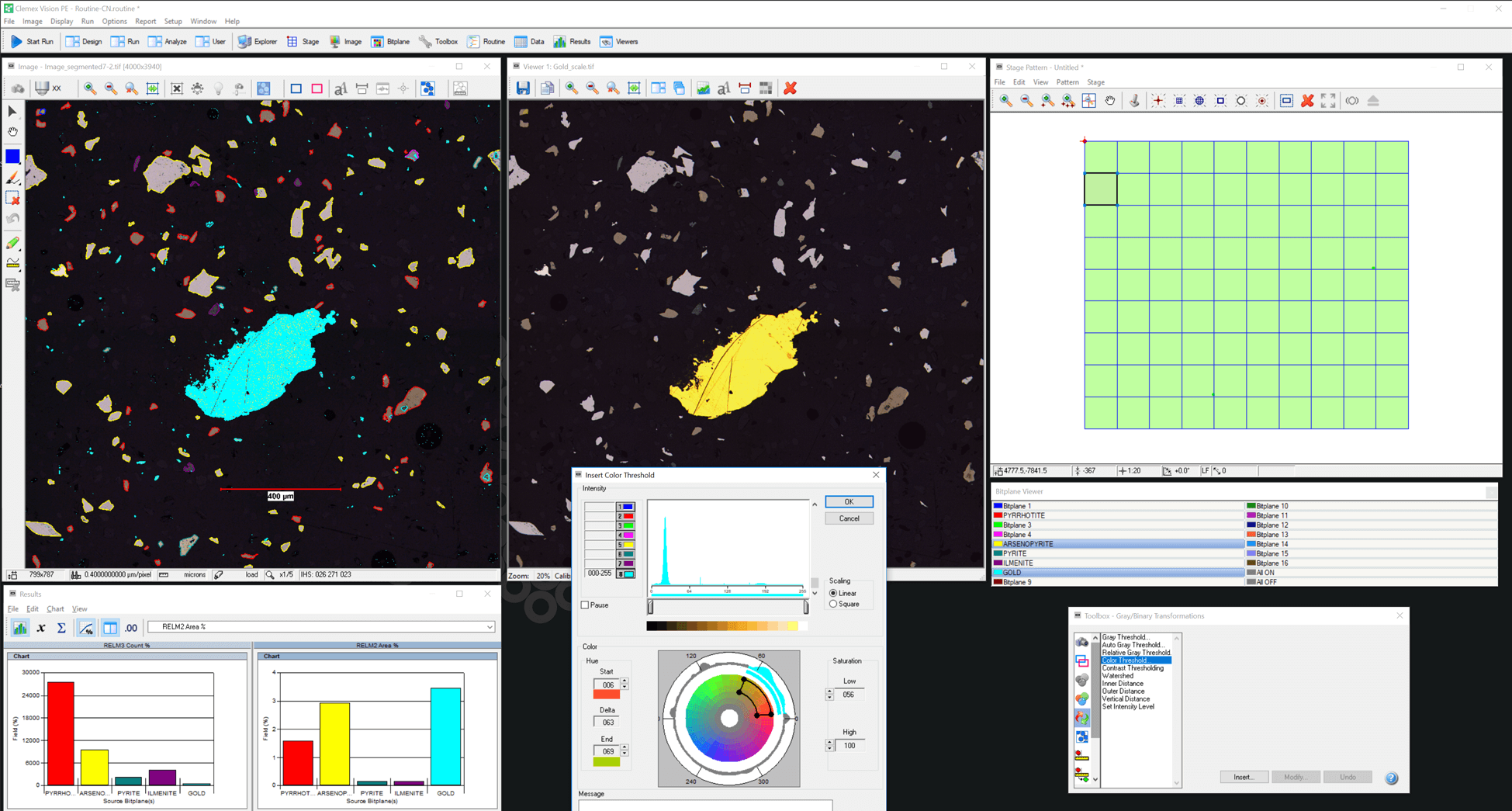

Détectez, caractérisez et mesurez des phases ou des objets d’intérêt à l’aide de notre vaste bibliothèque d’instructions. Vous pouvez facilement combiner n’importe quel ensemble d’instructions et créer votre propre routine.

INSTRUCTIONS SUR LA TAILLE DES GRAINS MARTENSITIQUES

L’importante fonctionnalité de la martensite est intégrée au début d’une routine d’analyse d’images automatisée pour détecter les limites des grains. Plusieurs paramètres permettent à l’utilisateur de régler la détection.

AUTOMATISATION PUISSANTE DES PROCESSUS

Grâce à ce logiciel robuste capable de traiter des milliers d’images et de générer des données tout au long de la journée sans intervention humaine, vous pouvez accélérer les temps d’analyse.

DONNÉES TRAÇABLES

Validez les fonctions détectées et supprimez les artéfacts sur plusieurs champs à l’aide de la fonction Map and Go. Les données d’objet de la feuille de calcul intégrée sont liées dynamiquement à la position réelle des objets sur l’échantillon.

PROPRIÉTÉS D’ANALYSE

Les informations des champs de propriétés peuvent être automatiquement insérées dans les rapports, les noms de fichiers ou les noms de dossiers. Utilisez des propriétés standard telles que le grossissement, la date ou le nom de l’échantillon, ou créez des champs personnalisés.

CRÉATION DE RAPPORTS AUTOMATISÉE

Les rapports sont générés automatiquement après chaque analyse et peuvent être adaptés en fonction de vos besoins. Ajoutez un logo d’entreprise, des images capturées pendant l’analyse, des graphiques et des statistiques, et enregistrez vos résultats sous forme de fichier csv, xlsx ou PDF.

ASSEMBLAGE D’IMAGES EN MOSAÏQUE

CONFORMITÉ À LA NORME CFR 21 PARTIE 11

Avec le module Gestion des droits d’utilisation, les administrateurs peuvent ajouter des utilisateurs, créer des groupes d’utilisateurs et suivre des événements dans la piste de vérification. Ce module en option permet l’intégration de signatures électroniques et est sécurisé et fiable.

PLUS DE FONCTIONNALITÉS

- DÉTECTION PRÉCISE

Détectez les objets difficiles à distinguer en raison de leur transparence, de leur faible contraste ou de leur faible luminosité. - CLASSIFIER DES OBJETS

Isolez des objets à l’aide de n’importe quel type de mesure (longueur, largeur, rapport d’aspect, rugosité, etc.). - INSTRUCTIONS CONDITIONNELLES

Analysez des objets qui répondent à certains critères, tels que la taille, la forme ou l’orientation.

- MESURES DIRECTES ET ANNOTATIONS

Annotez vos images à la volée pendant votre analyse; incluez les résultats et les visuels dans les rapports. - PROFONDEUR DE CHAMP ÉTENDUE

Obtenez une image composite nette composée de plusieurs coupes d’image, parfaite pour les surfaces inégales. - COMMANDE DE DISPOSITIF EXTERNE

Activez les dispositifs externes tels que les vannes, les dispositifs de verrouillage, les alarmes et les voyants. - OPTIMISATION DE L’IMAGE

Correction des ombres, exposition automatique, balance des blancs, mise au point automatique, foyer et paraxialité pour chaque grossissement. - CONTRÔLE DE LA PLATINE MOTORISÉE

Contrôlées par le logiciel, les régions de saisie peuvent être définies à l’aide de modèles prédéfinis.

- ÉTALONNAGE NIST

Élimine la subjectivité de l’opérateur en étalonnant automatiquement chaque lentille à l’aide d’un micromètre NIST. - SÉPARER LES OBJETS

Séparez automatiquement les objets contigus avant d’effectuer des mesures. - AUTOMATISATION DE LA RÉGION DE SAISIE

Création automatique de modèles de platine en fonction des objets détectés ou des points de référence d’échantillon. - IMAGES TIERCES

Importez des images provenant de diverses sources, telles que des microscopes électroniques à balayage ou des numériseurs à balayage.

VISION CORE

VISION LITE

CAPTIVA

Manette virtuelle pour platine motorisée et mise au point automatique

✓

✓

✓

Enregistrer et exporter les mesures

auto.

auto.

man.

Enregistrer et exporter des images

✓

✓

✓

Mesures et annotations manuelles

✓

✓

✓

Générateur de rapports

en option

en option

S.O.

Routines illimitées

✓

outils limités

S.O.

Mesures automatiques (champ/objets)

✓

✓

S.O.

Mesures personnalisées (champ/objets)

✓

✓

S.O.

Seuillage

et traitement

✓

✓

✓

S.O.

S.O.

S.O.

Opérations avancées

✓

en option*

S.O.

Transfert automatique

✓

en option*

S.O.

* offert avec un ou plusieurs modules d’application

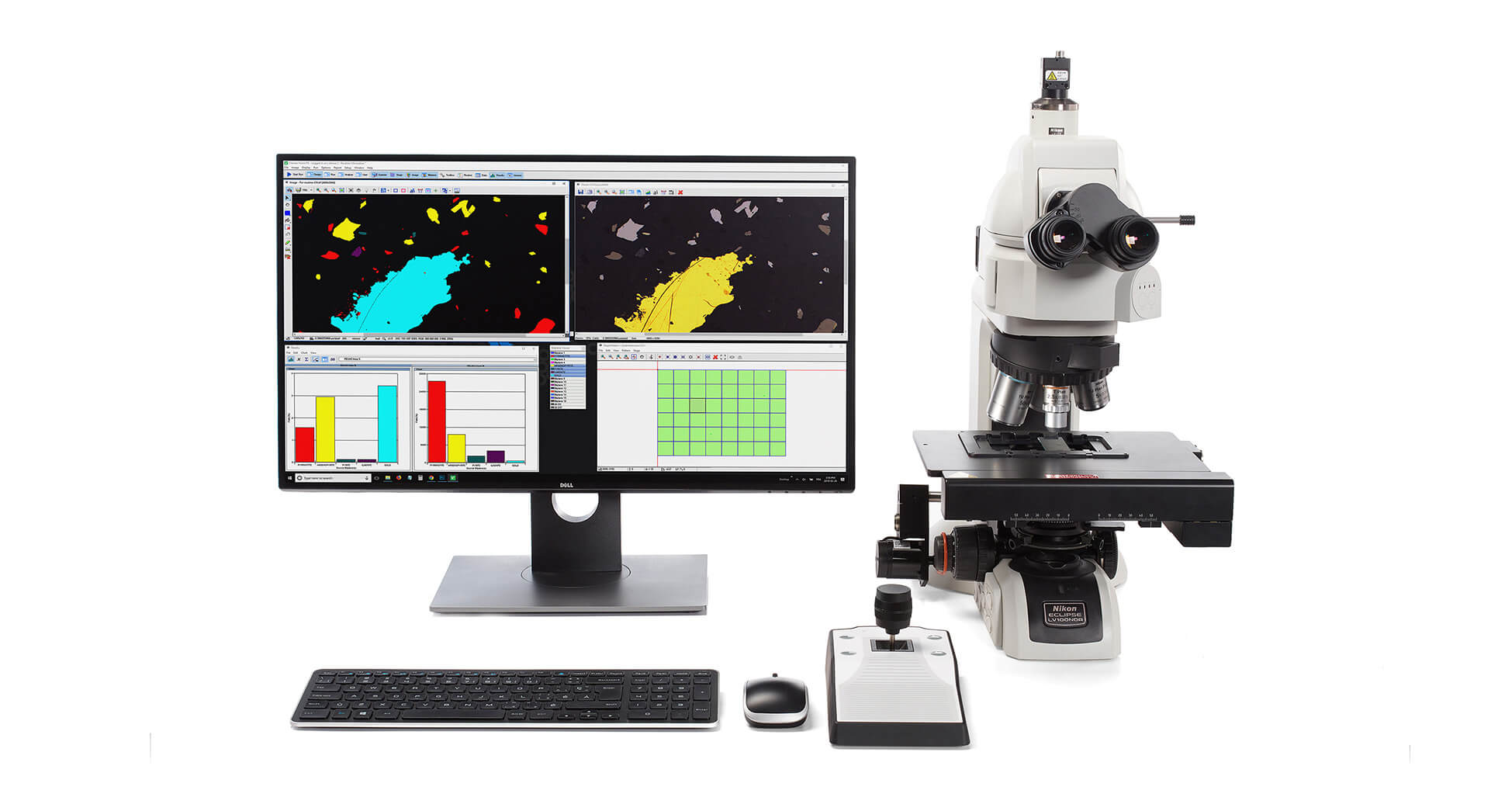

CRÉEZ VOTRE SOLUTION COMPLÈTE D’ANALYSE D’IMAGES

En général, un microscope vertical, une platine motorisée et une caméra haute résolution sont sélectionnés pour répondre à vos besoins particuliers en matière d’analyse d’image. Nous assurons une intégration transparente de tous les composants.

- Analyse de vos besoins par un représentant technique

- Configuration, réglage fin et étalonnage

- Installation sur site et formation de votre équipe

Augmentez la productivité dans un laboratoire à haut débit grâce à un flux de travail très simple. L’opérateur suit une procédure en trois étapes pour obtenir des résultats reproductibles :

- Positionner un échantillon sur la platine

- Lancer une analyse sur l’échantillon

- Examiner les données et exporter les résultats

CAMÉRAS

Caméras haute résolution adaptées aux applications d’imagerie optique exigeantes.

MICROSCOPES NIKON

Nous intégrons des microscopes Nikon stéréo, droits et inversés de qualité.

MICROSCOPES LEICA

Nous intégrons des microscopes Leica stéréo, droits et inversés de qualité.

PLATINES POUR MICROSCOPES

Les platines, contrôleurs et joysticks Märzhäuser-Wetzlar fonctionnent avec de nombreuses marques différentes de microscopes.

ACCESSOIRES POUR SUPPORTS PERSONNALISÉS

Nous concevons et fabriquons une large gamme de porte-échantillons et d’adaptateurs de platine, fabriqués pour répondre aux spécifications de tous les clients.

MICROMÈTRE DE PLATINE

Le micromètre de platine Clemex pour l’étalonnage automatique et la correction d’ombrage est fourni avec un certificat de traçabilité selon NIST.