HIGH PRECISION

CLEANLINESS ANALYSIS

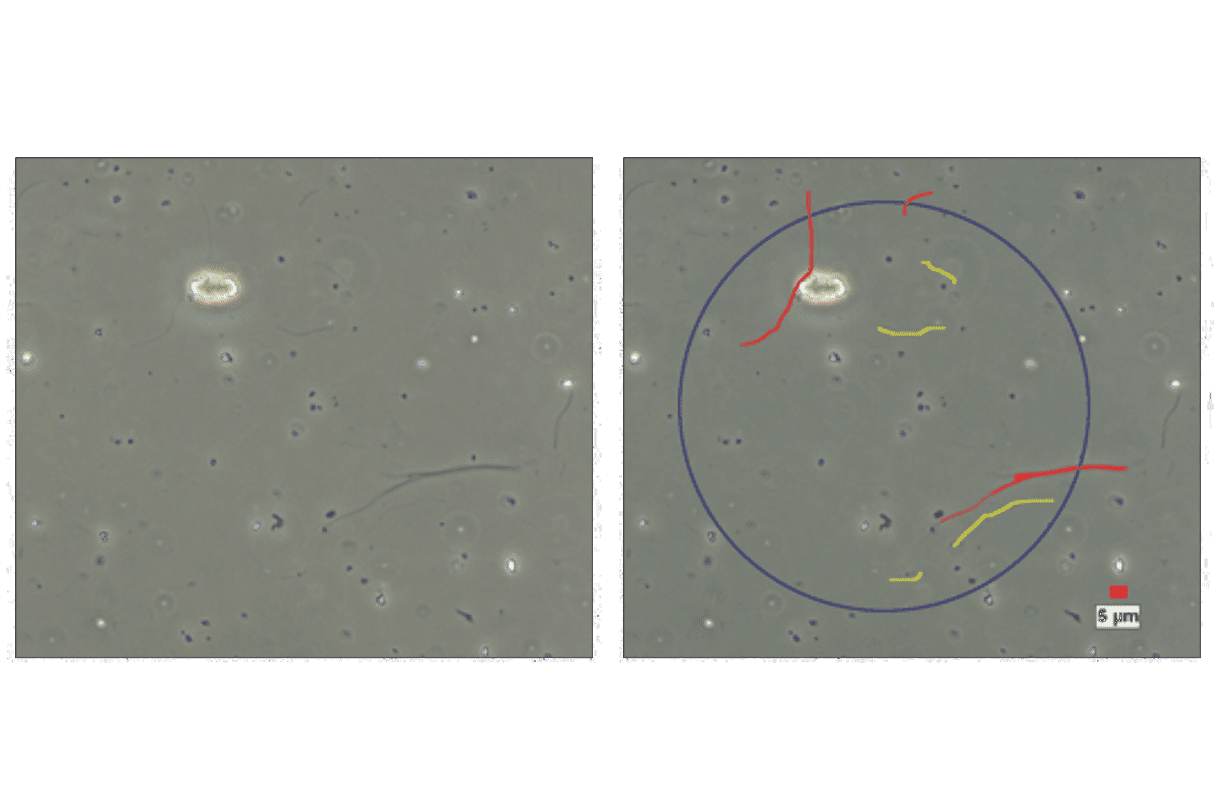

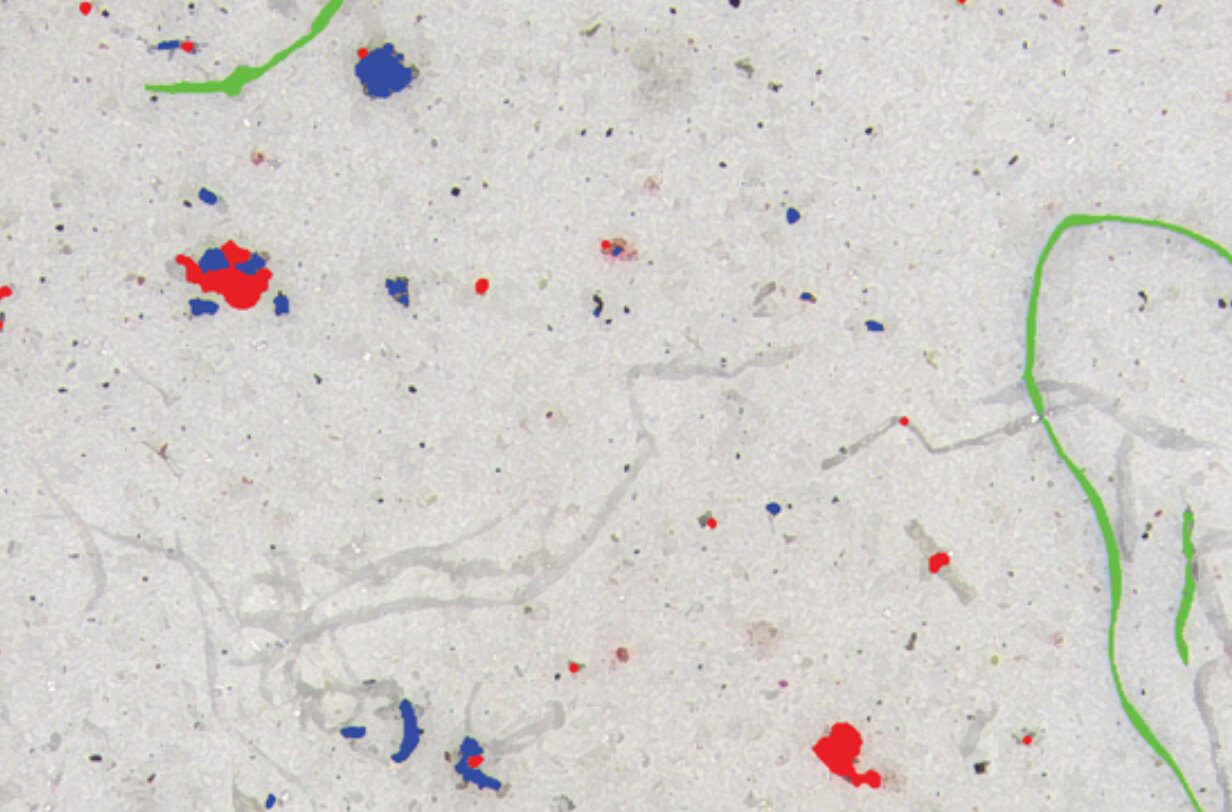

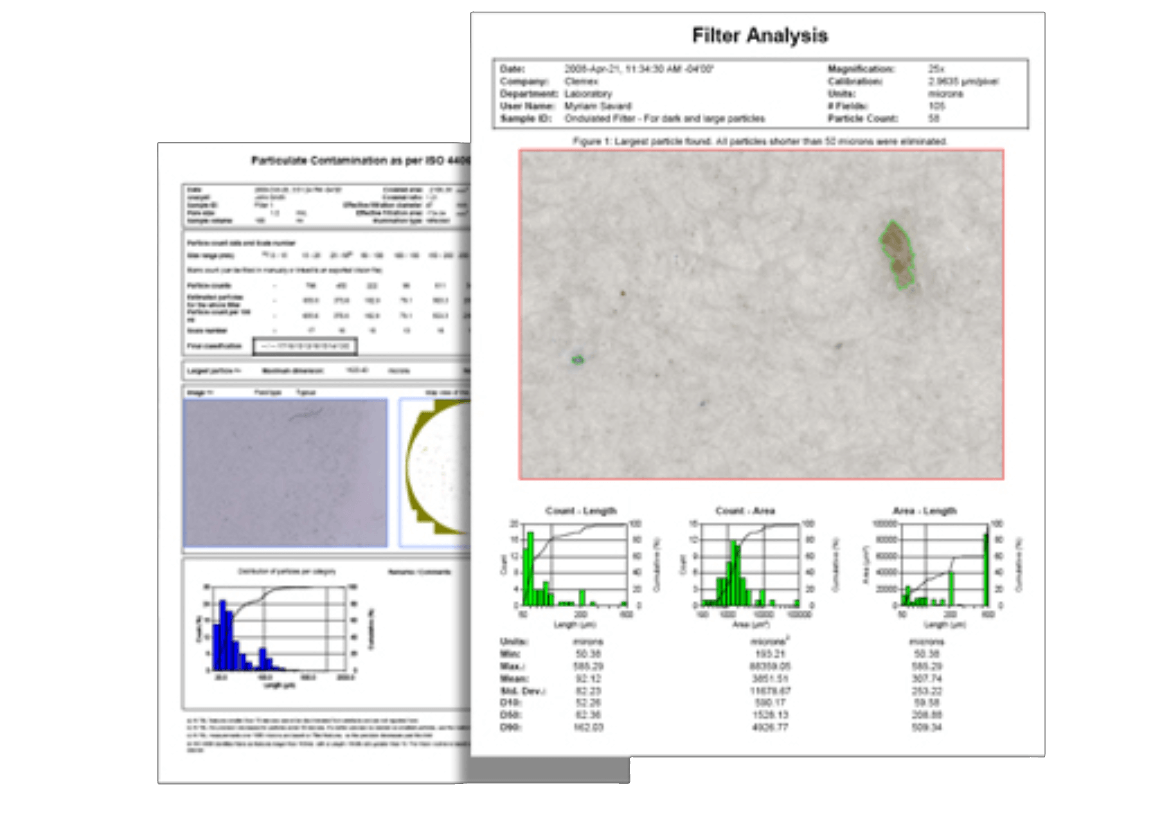

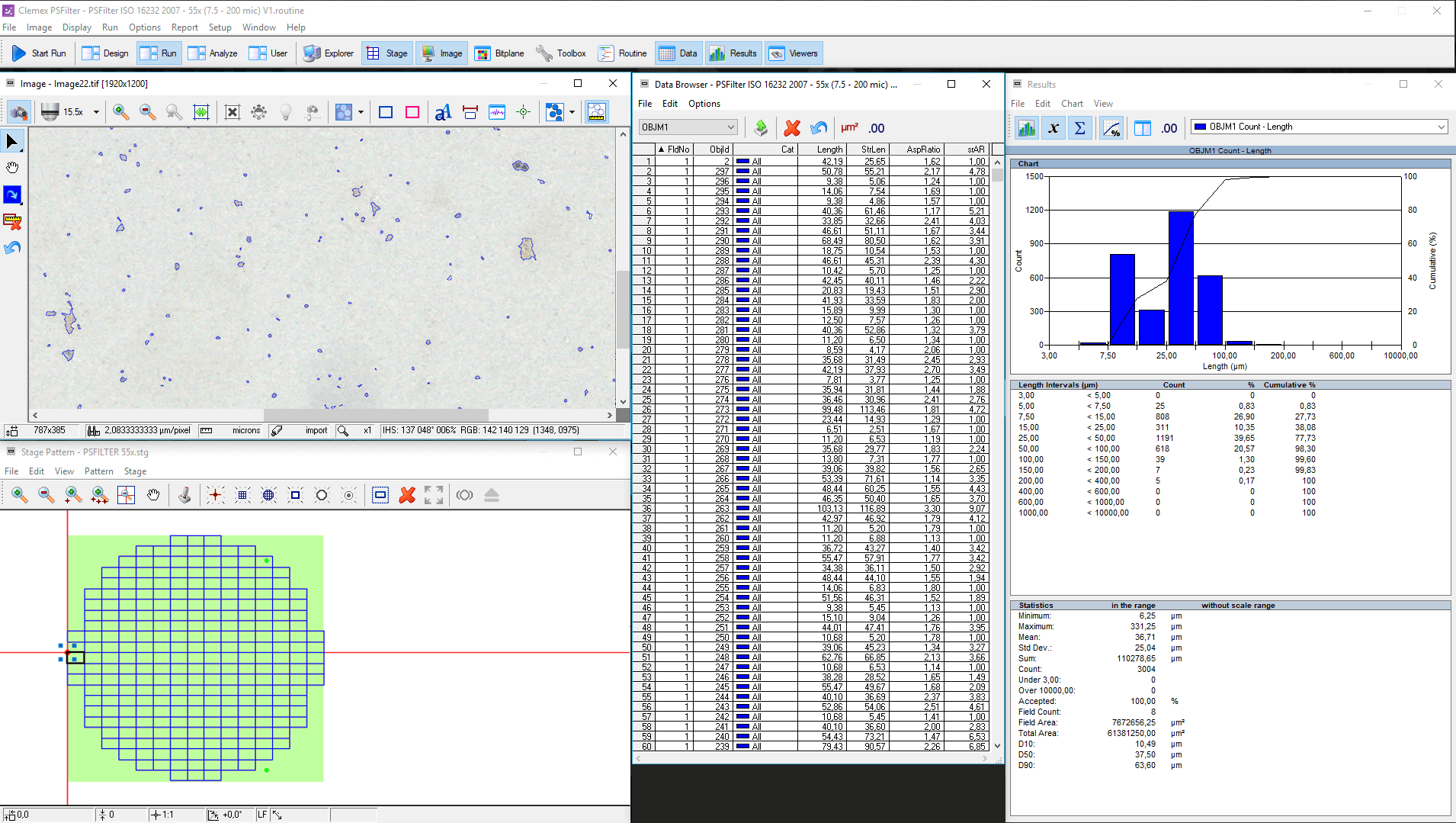

The measuring of particle contamination is of the utmost importance in the manufacturing and pharmaceutical industries. Damage caused by these particles can often have detrimental effects in machinery and harmful effects in pharmaceuticals. That is why the Clemex PSFilter is specially designed to analyse contamination in different areas by measuring particles collected on membrane filters, wafers, tape lifts, or gel packs.

TYPES OF

ANALYSIS

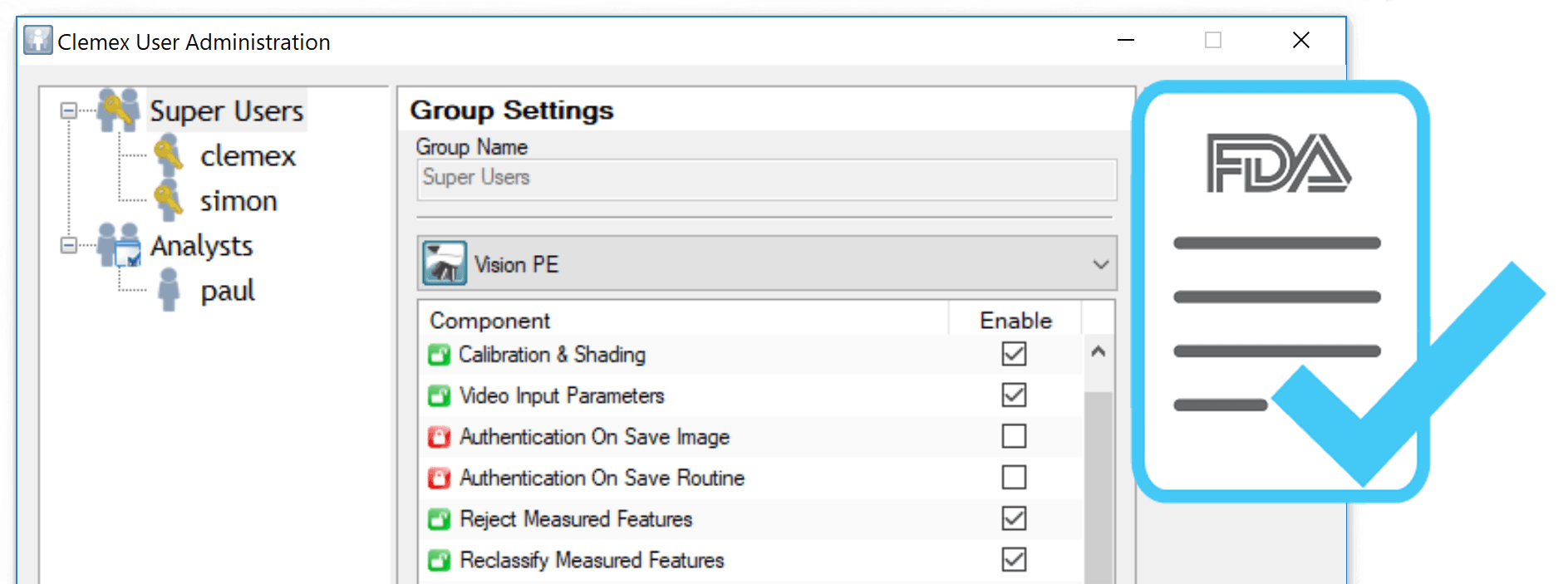

Clemex PSFilter allows to choose from pre-programmed International Standards such as IEST-STD-CC1246D, ISO 16232, ISO 4406-4407, or USP 788. It also offers the option of customizing its properties so that in-house standards can be applied.

ISO 16232

ISO 4406 & 4407

IEST STD CC1246D

USP 788

Types of samples

Membrane filters

Silicon wafers as witness plates

Tape lifts

Gel-Pak products

KEY

FEATURES

MORE FEATURES

ACCURATE DETECTION

Detect objects that are difficult to distinguish because of their their transparency, low contrast or faint outlines.

CLASSIFY OBJECTS

Isolate objects using any measurement type (length, width, aspect ratio, roughness, etc.).

CONDITIONAL INSTRUCTIONS

Analyze objects that meet certain criteria, such as size, shape or orientation.

DIRECT MEASURES & ANNOTATIONS

Annotate your images on-the-fly during your analysis; include results and visuals in reports.

EXTENDED DEPTH OF FIELD

Obtain a sharp composite image made up of several image slices, perfect for uneven surfaces.

EXTERNAL DEVICE CONTROL

Activate external devices such as valves, locking devices, alarms, lights.

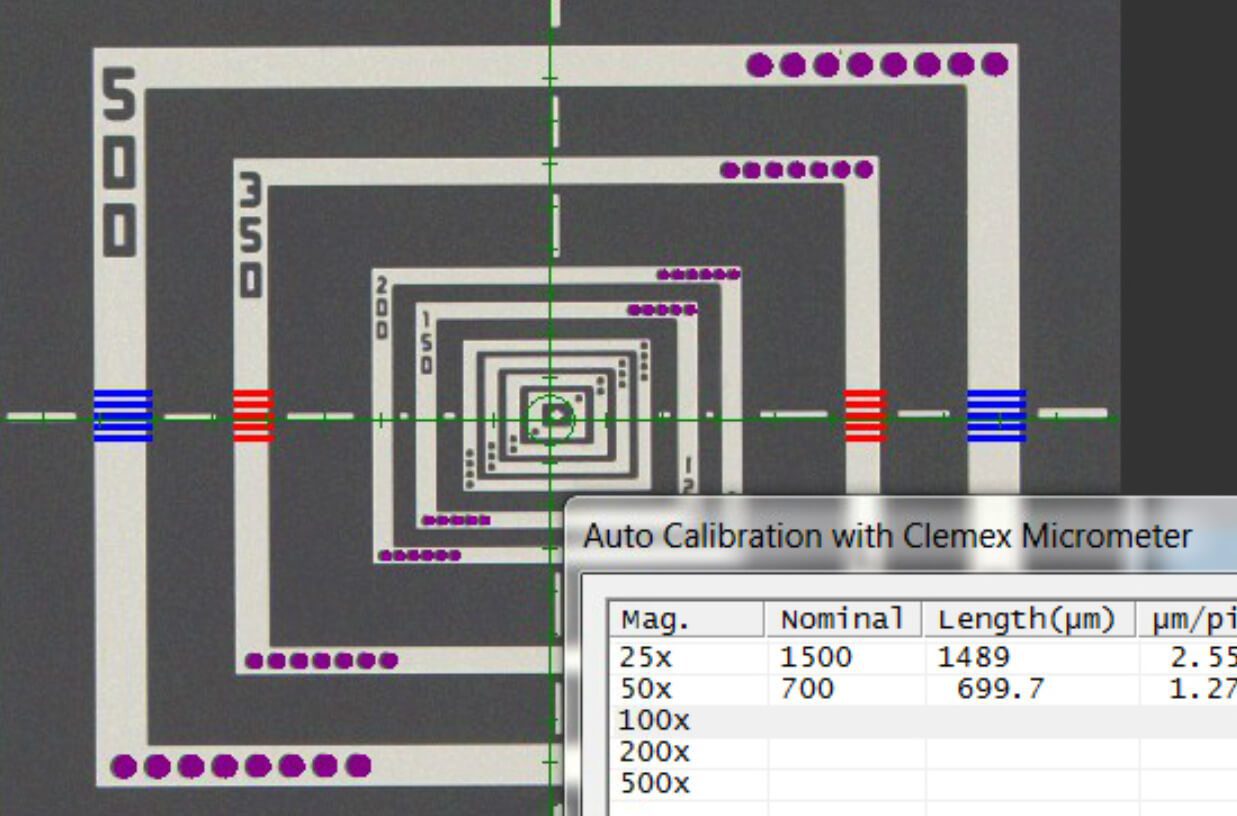

IMAGE OPTIMIZATION

Shading correction, auto-exposure, white balance, auto-focus, parfocality and paraxiality for each magnification.

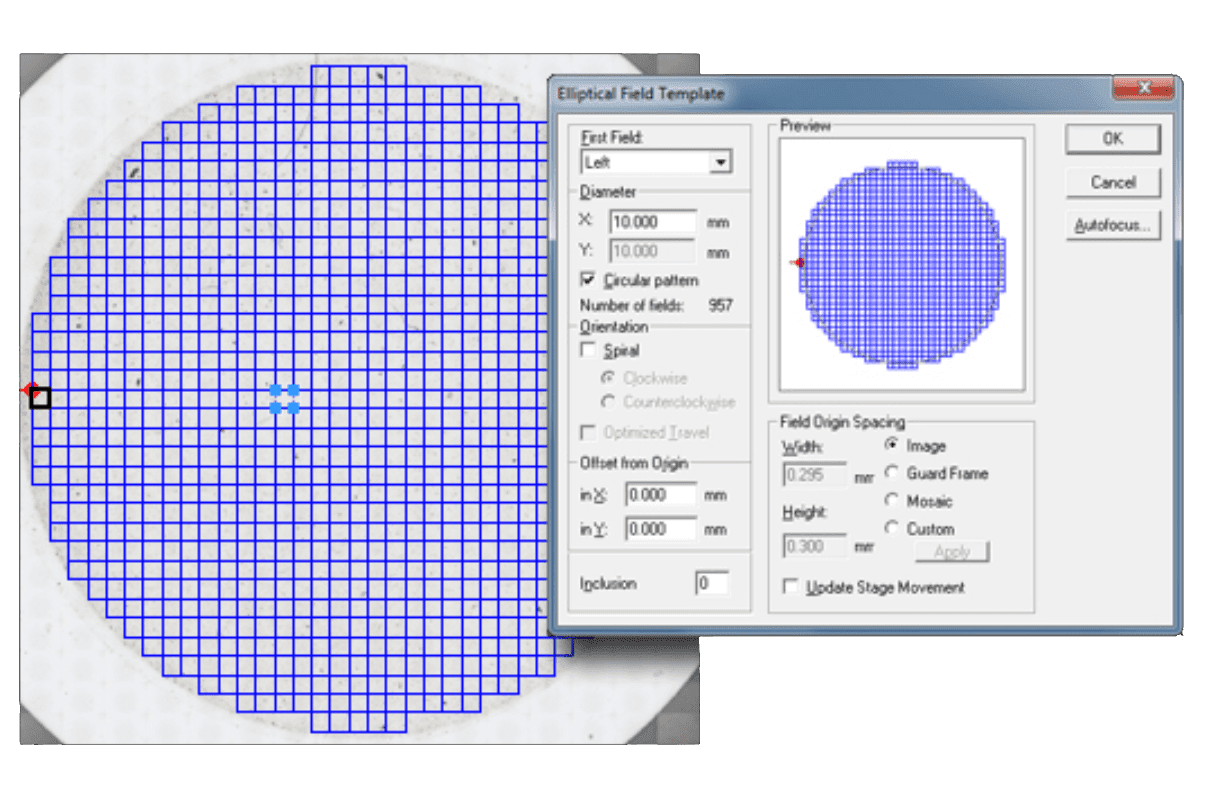

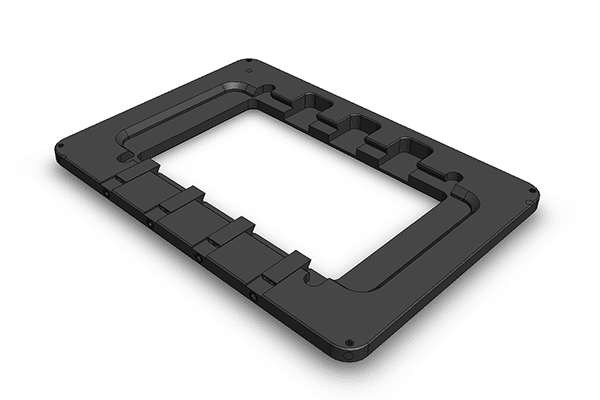

MOTORIZED STAGE CONTROL

Controlled through the software, scanning regions can be defined using pre-built templates.

SEPARATE OBJECTS

Separate adjacent objects automatically prior to performing measurements.

SCAN REGION AUTOMATION

Automated stage pattern creation based on detected objects or sample reference points.

THIRD PARTY IMAGES

Import images from various sources, such as SEMs or scanners.

PRODUCT

DETAILS

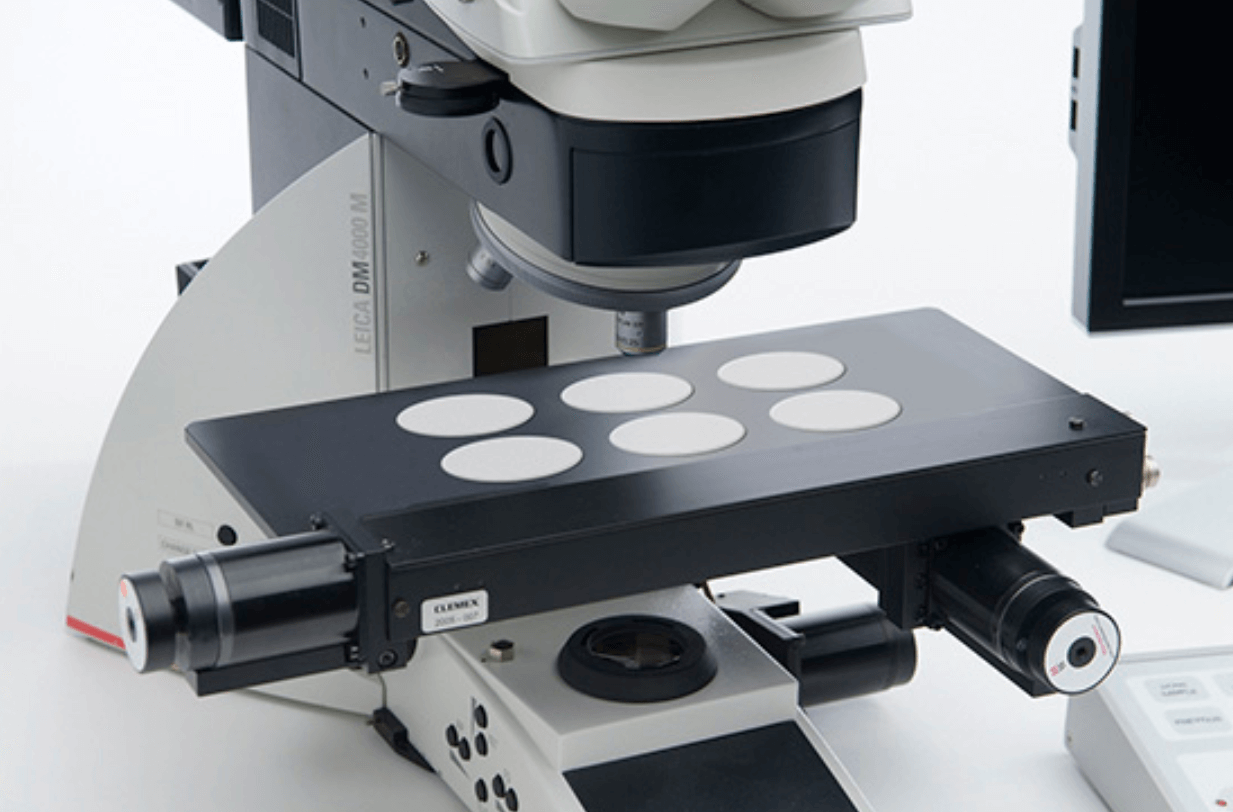

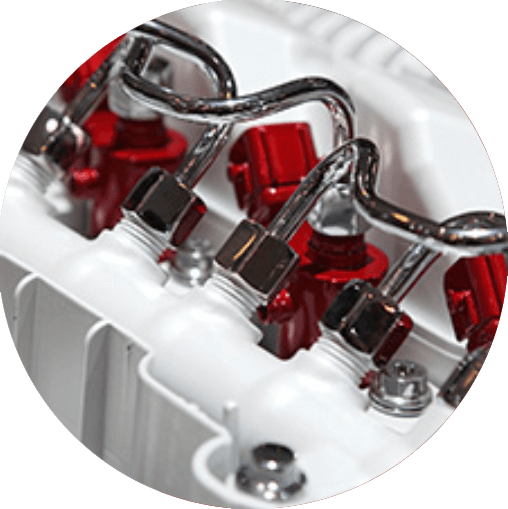

Typically an upright microscope, a motorized stage, and a high-resolution camera are selected to fit your specific image analysis needs. We ensure a seamless integration of all components.

- Analysis of your needs by a technical representative

- Configuration, fine-tuning, and calibration

- On-site installation and training of your team

HARDWARE &

ACCESSORIES

DOWNLOAD OUR

BROCHURES