CLEMEX

POWDER DISPERSER

The Clemex Powder Disperser is a free-flowing powder disperser used to “uncluster” particles. Once the process is complete, the particles are easier to observe and measure on glass slides using optical microscopy.

FEATURES

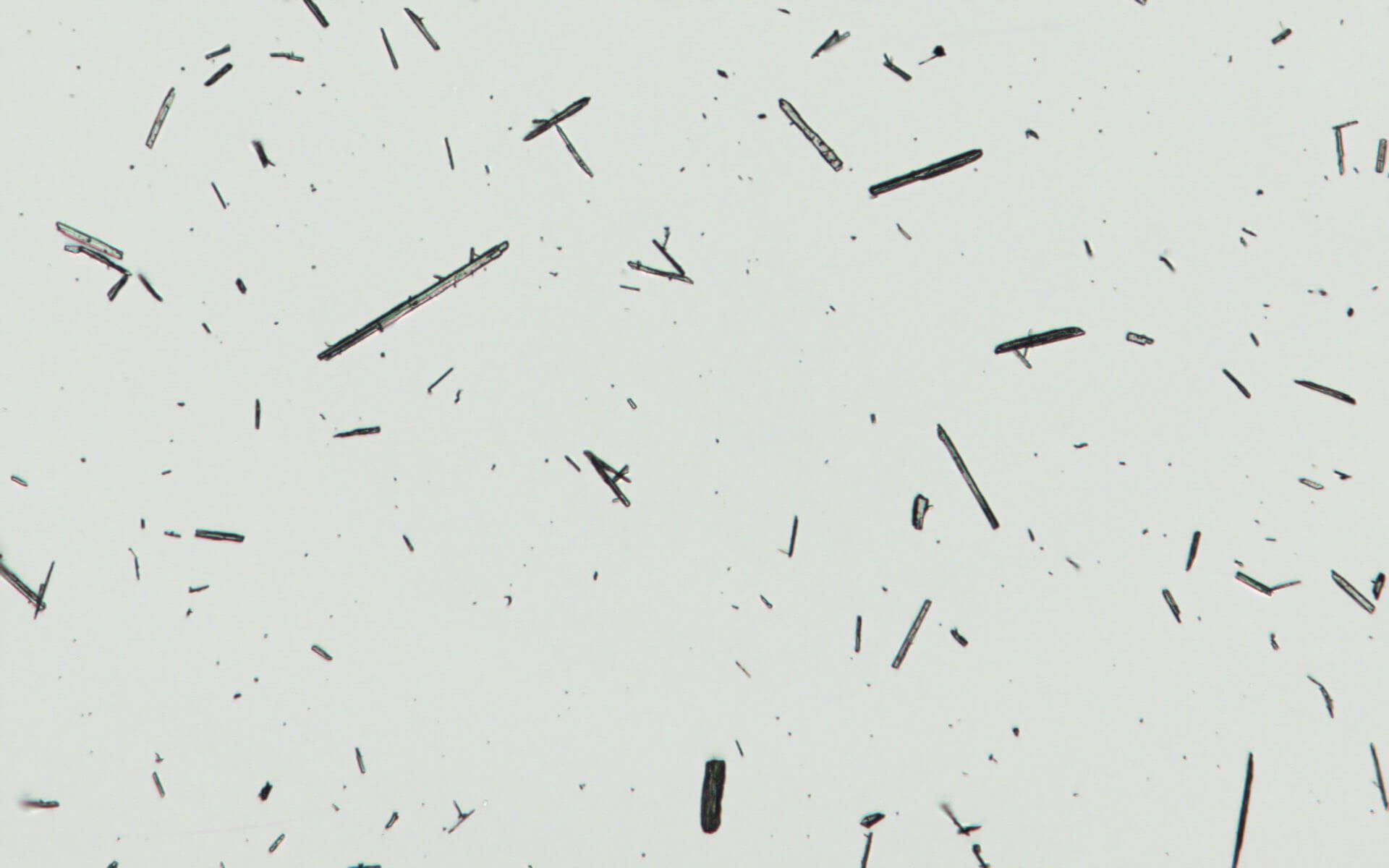

PERFECT DISPERSION

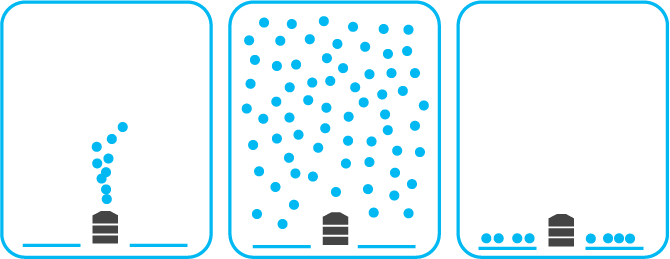

When the powder is pushed into the vacuum tube, the particles slowly fall onto the glass slides positioned on each side of the dispersal nozzle. Once they land, the particles are no longer bunched up or clustered, making for a much clearer viewing experience.

COMPUTER CONTROLLED

The Clemex Powder Disperser is software-controlled, allowing the user to modify the starting pressure, dispersion flow, and dispersion time. Saved settings can be reused with one click to activate the disperser.

OTHER FEATURES

- No damaged particles

- Reliable and repeatable

- Pre-defined settings for various particle types

- Vacuum system avoids surrounding contamination

- Easy to clean

PARTICLE DISPERSION

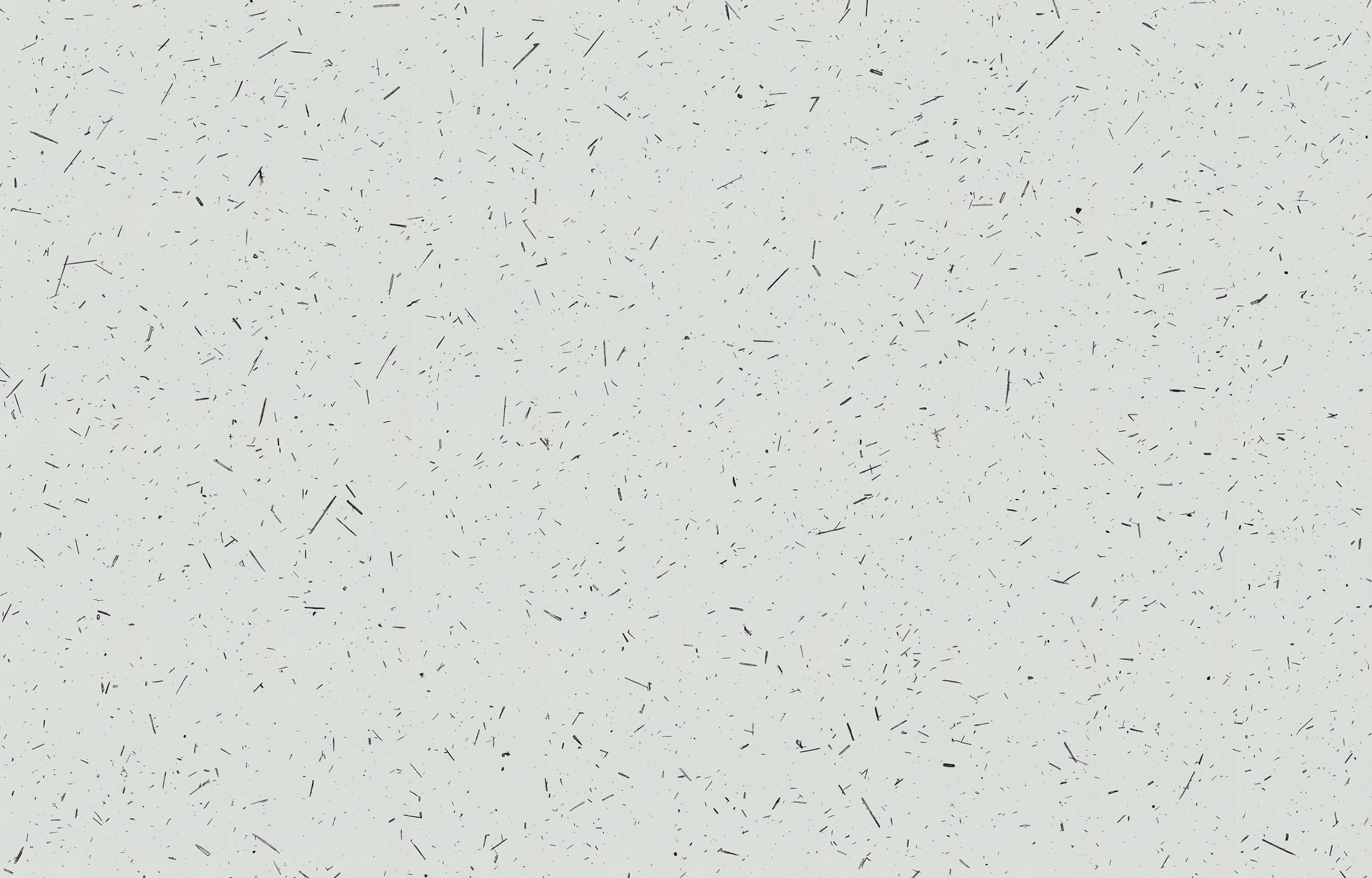

UNDISPERSED PARTICLES

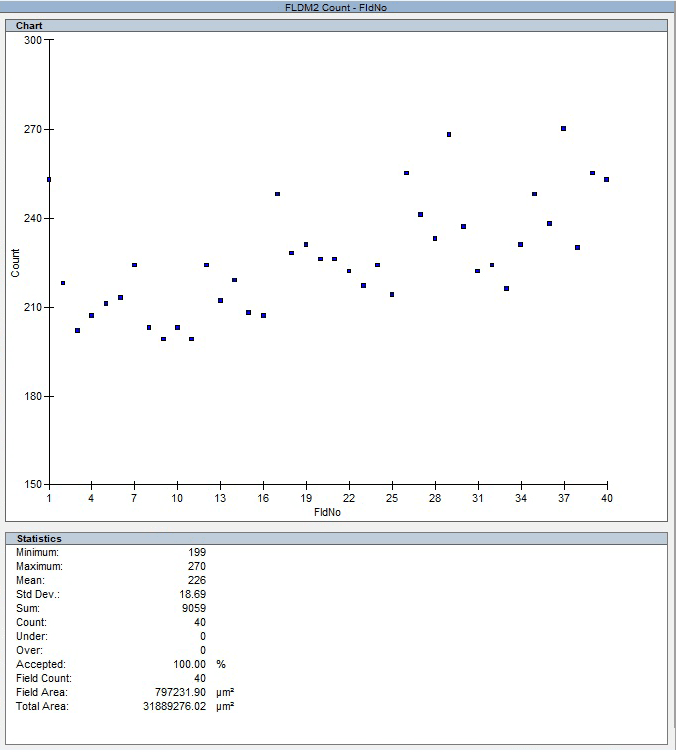

Fig. 1 Rod-shaped pharma powder dispersed manually. Mosaic of 40 images taken at 100X.

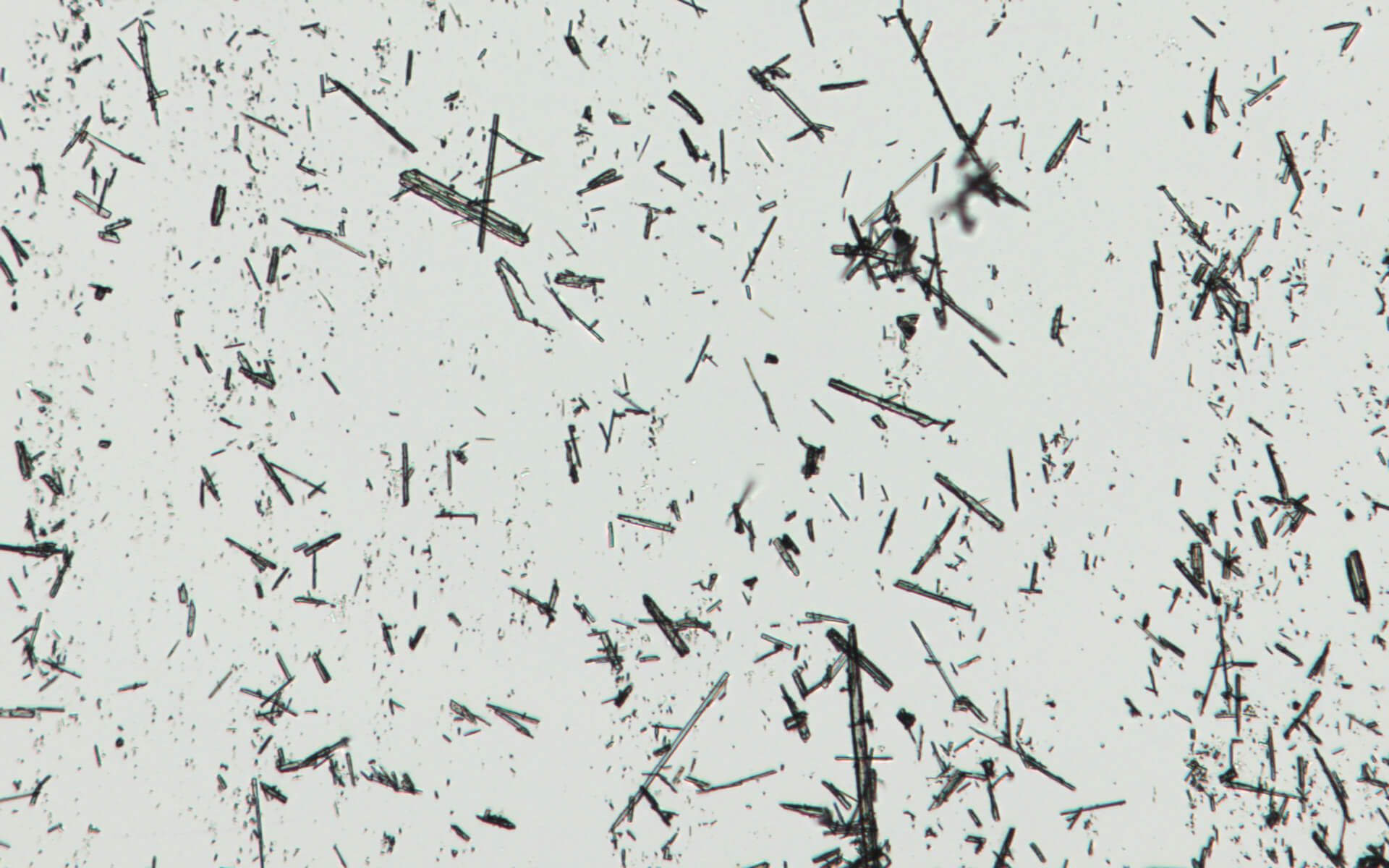

TYPICAL FIELD

Fig. 3 These particles tend to overlap and cluster, making detection using image analysis almost impossible.

CONCLUSION

Undispersed powder, such as this needle shaped pharmaceutical ingredient, tends to aggregate when placed on a glass slide. Overlapping or touching particles are impossible to measure accurately using image analysis as the size of these clusters will produce biased particle size and shape results. Excluding these clusters from the analysis would also create a bias, as larger particles tend to aggregate more than smaller ones.

CONCLUSION

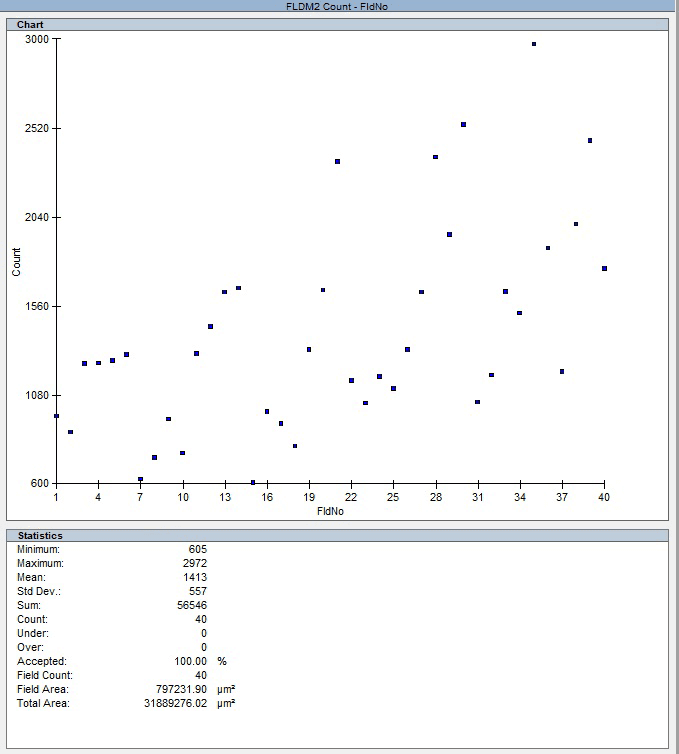

From the field analysis, the plots and statistics results clearly illustrate that the particles are distributed more equally and uniformly using a Clemex Powder Disperser. Most particles are isolated and can therefore be easily detected as individual objects using image analysis. This ensures reliable results when analyzing the size and shape distribution of the particle population.