Image Analysis for the

Metal Industry

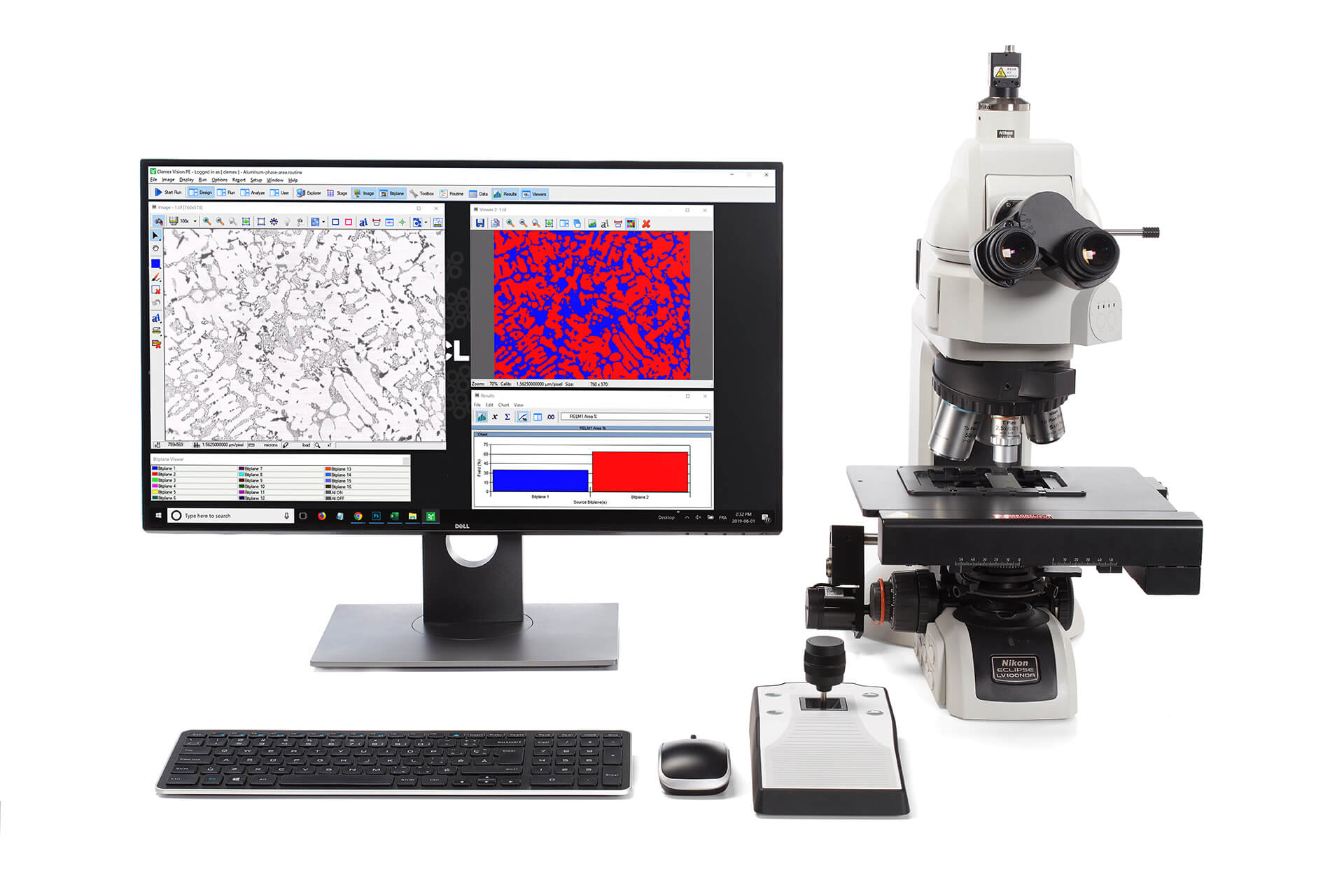

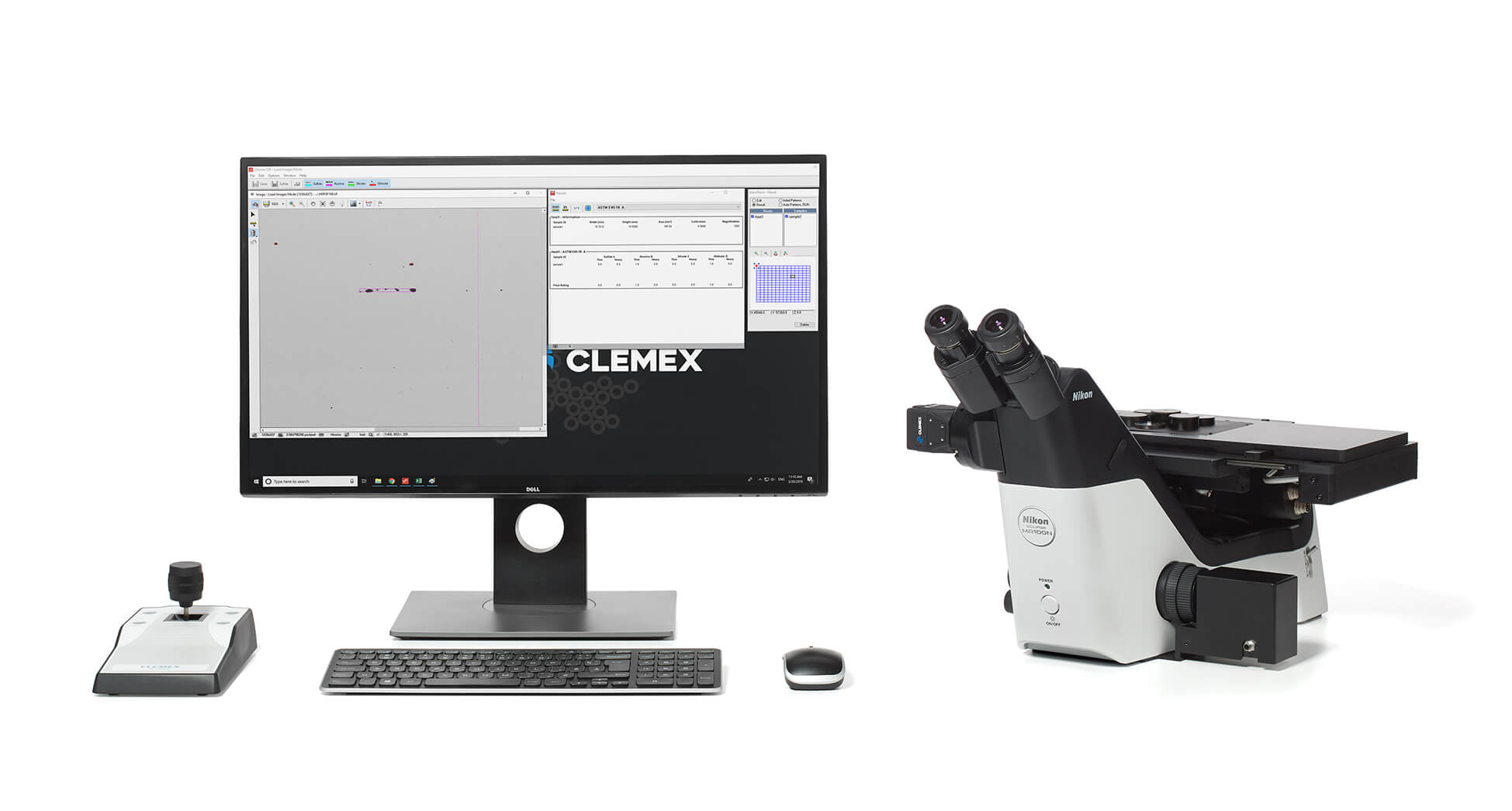

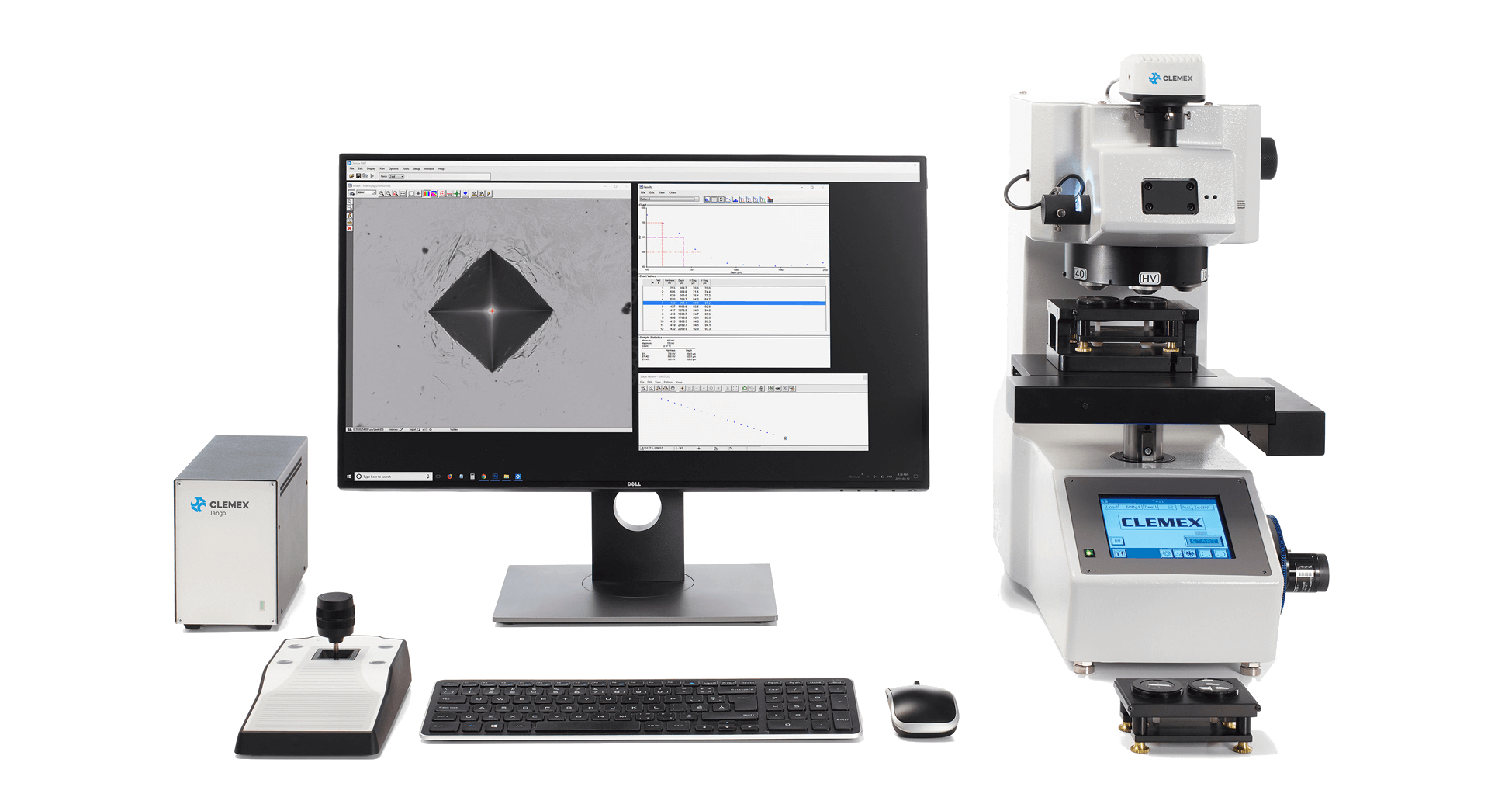

Customer material testing facilities equipped with our systems are able to adapt any industry standard to their testing procedure. Common tests on incoming and outgoing materials rely on efficient microstructure analysis, such as nodularity, porosity, inclusions, grain size, inverse segregation, phase area and DAS. Clemex systems perform these measurements day in day out with minimum user input and with unsurpassed reliability.

SOLUTIONS

APPLICATIONS

Our image analysis software is exceptionally flexible, allowing for any number of distinct routines to be run on the same system. These routines come packaged as a library of existing applications or can be developed by our applications specialists.

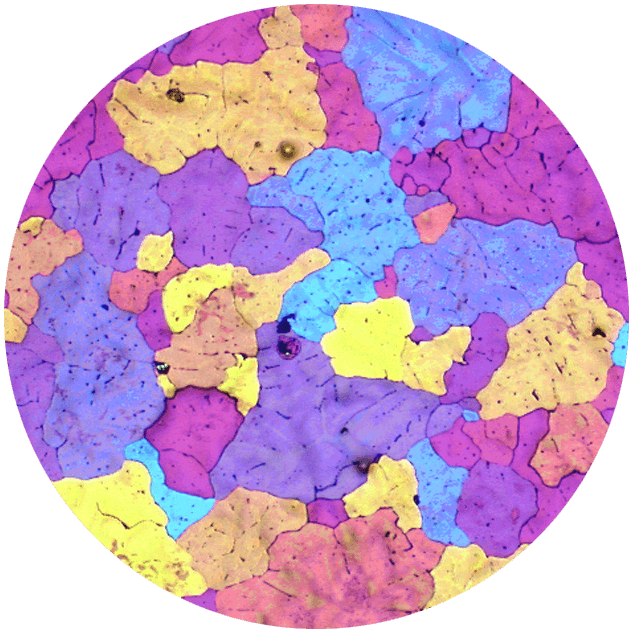

Image Analysis Applications for Steel

- Non-metallic inclusion rating

- Grain size distribution as per ASTM E112

- Banding or orientation of microstructures

- Depth of decarburization as per ASTM E1077

- Phase analysis in duplex stainless steel

- Hardness testing

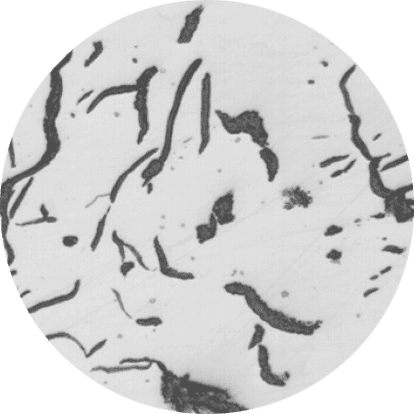

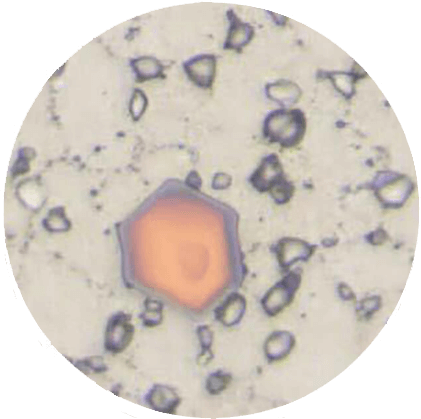

Image Analysis Applications for Cast Iron

- Maximum size of flakes, longest flake

- Area percent of porosity and nodularity

- Flake size as per ASTM A247

- Flake size as per ISO 945

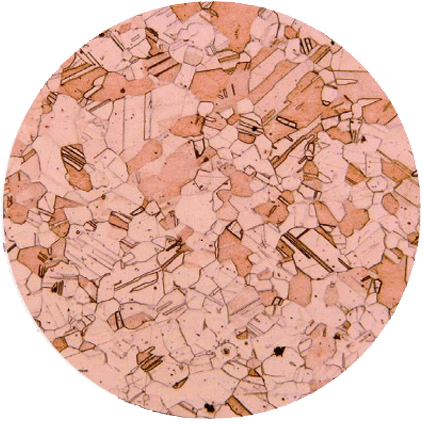

Image Analysis Applications for Aluminum Alloys

- Grain size distribution as per ASTM E112

- Area percent of Mg2Si particles

- Particle size measurement

- Dendritic arm spacing

- Porosity percentage

Image Analysis Applications for Superalloys

- Carbide analysis in nickel-based alloy

- Coating and Inconel characterization

- Hydride orientation on zirconium alloy

- Gamma prime particle analysis in nickel alloy

- Dihedral angle in tungsten alloy

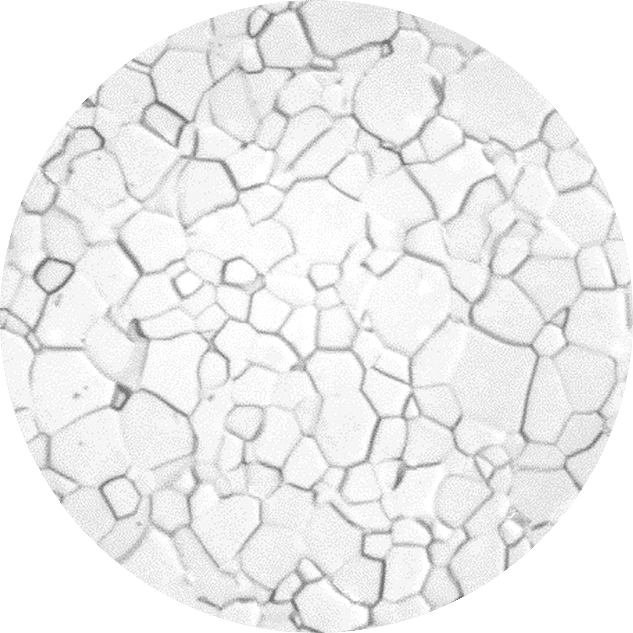

Image Analysis Applications for Copper Alloys

- Dendritic arm spacing in copper lead alloy

- Grain size analysis in copper

- Mineral phase area percent

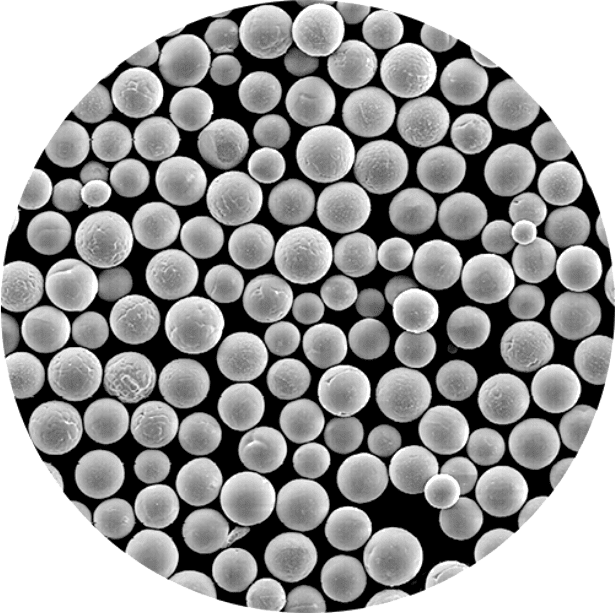

SEM Image of Tantalum Powder courtesy of Tekna

Image Analysis Applications for Metal Powders

- Size and shape of metal powder particles

- Sphere characterization in SEM images

- Assessment of sub-micron sizes of metal powder particles