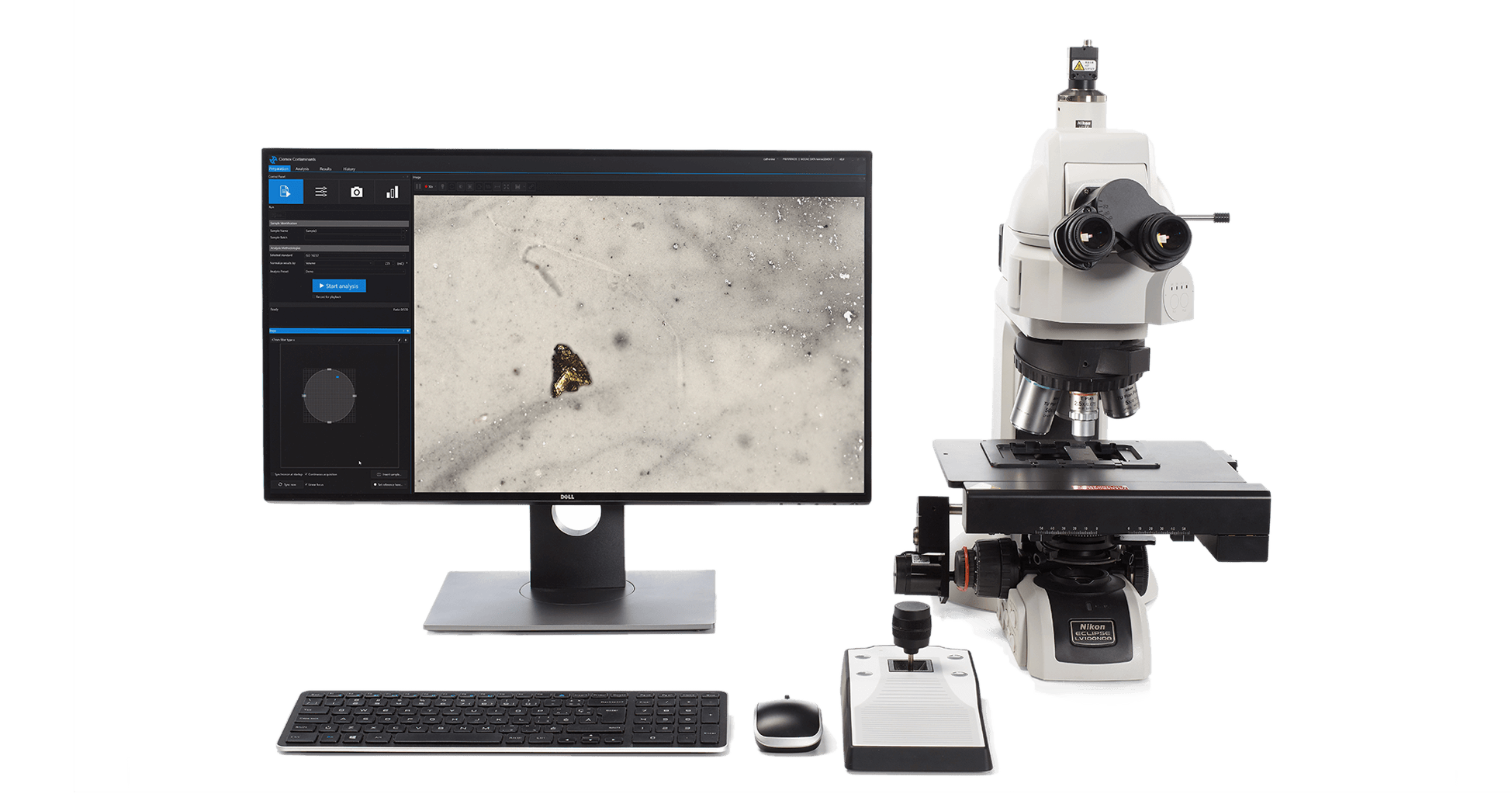

Cleanliness analysis as per ISO 16232

ISO 16232 and VDA 19 define the standards to ensure quality and reliability of the components for automotive sector and its suppliers. In this example, one membrane filter sample was submitted for particulate contamination determination and identification according to ISO 16232.

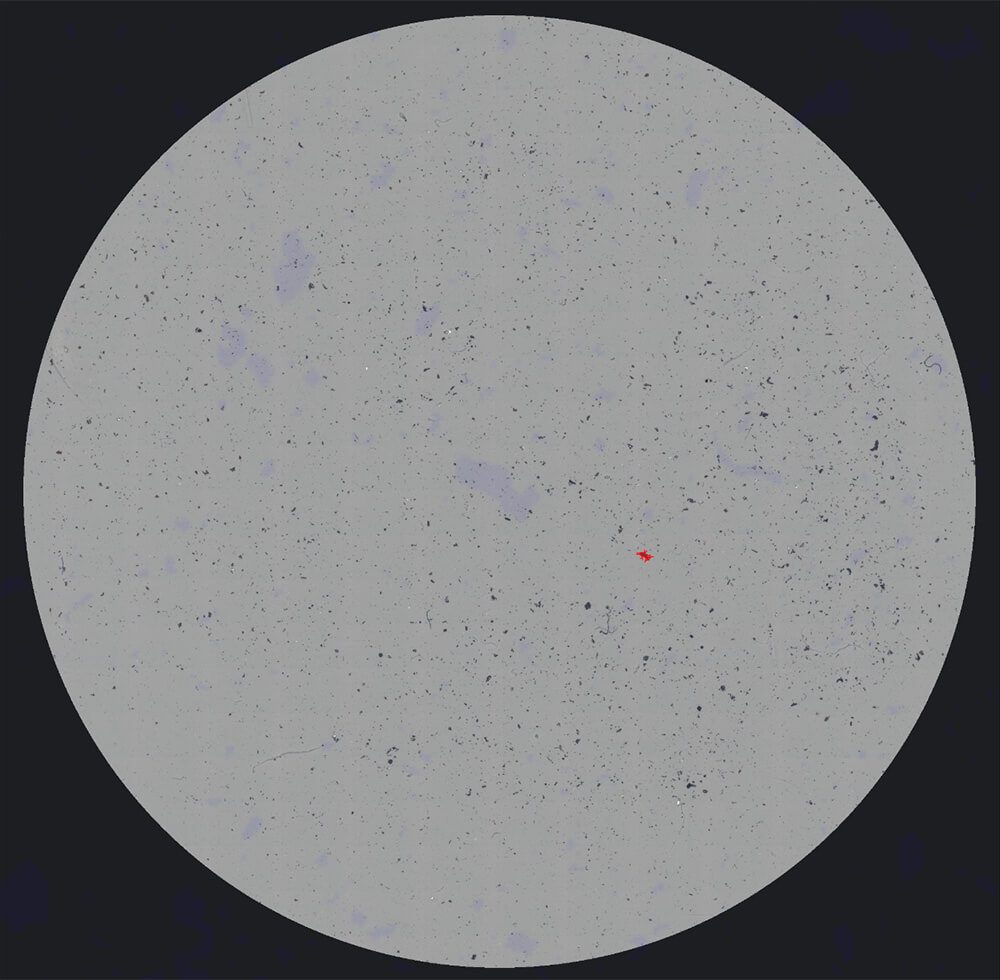

Figure 1. Mosaic of filter at 50x

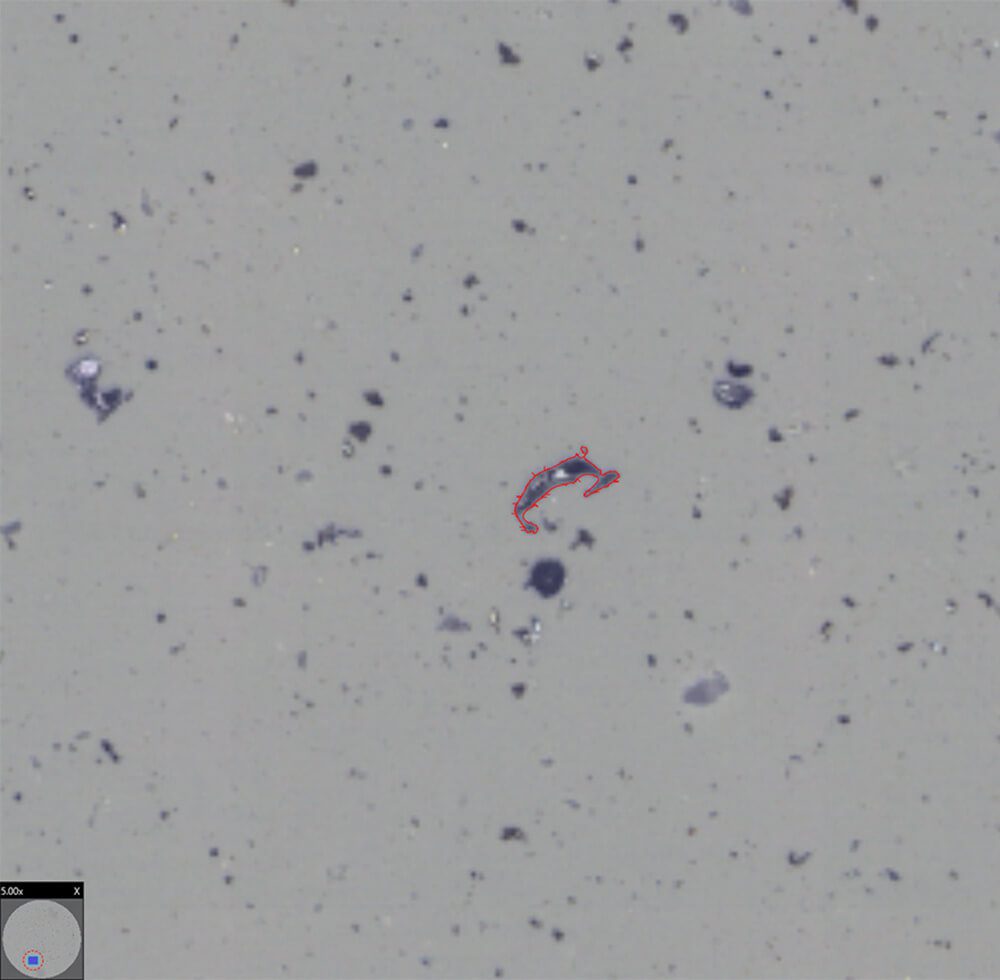

Figure 2. Largest metallic particle

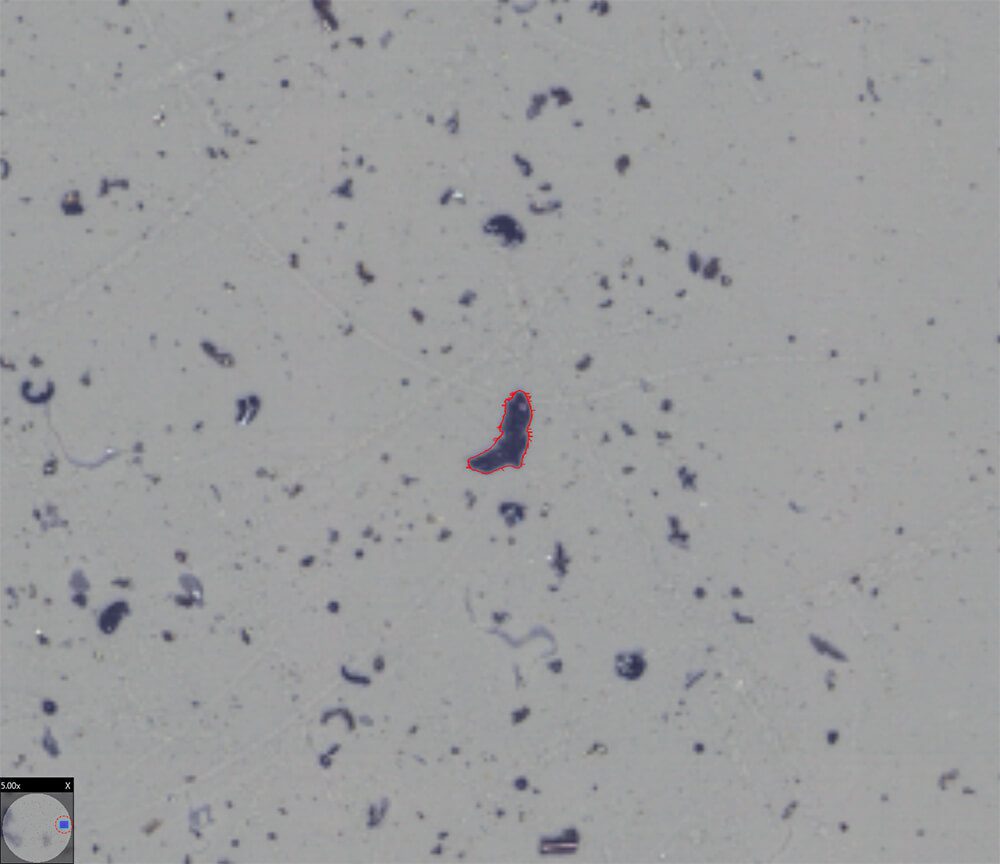

Figure 3. Largest non-metallic particle

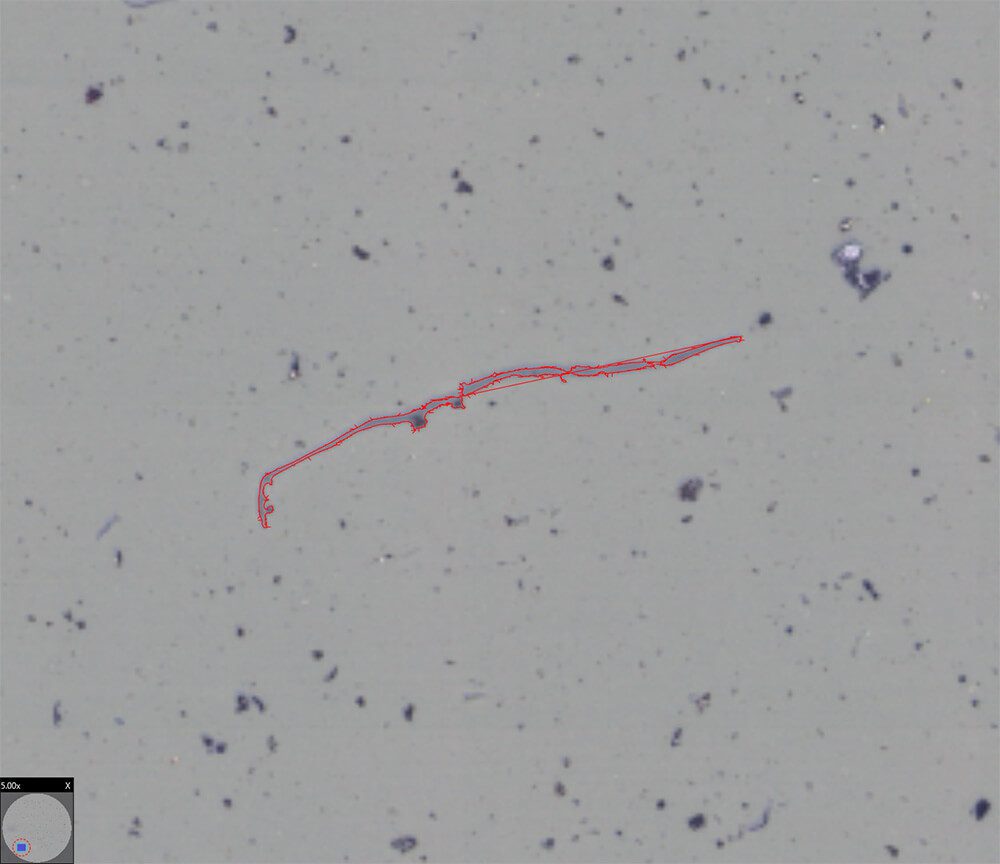

Figure 4. Largest fiber

PURPOSE

Demonstrate the ability of Clemex Contaminants to automatically identify, measure and classify particles with respect to ISO 16232. The technical report is linked at the bottom of this page (click the Download PDF link below).

RESULTS

The whole area of the filter was scanned during the analysis. The sizes of different particles were measured and classified based on the ISO 16232. Final results can be printed directly from Clemex Contaminants. Raw data can be exported in Excel format.