Grain Size in Austenitic Steel

One austenitic stainless steel image is submitted for analysis. Etch stains, polishing artifacts, and carbide precipitates in the grain or at grain edges make traditional thresholding inconsistent. A machine-learning algorithm specifically developed for austenitic grains allows a reliable one-step segmentation.

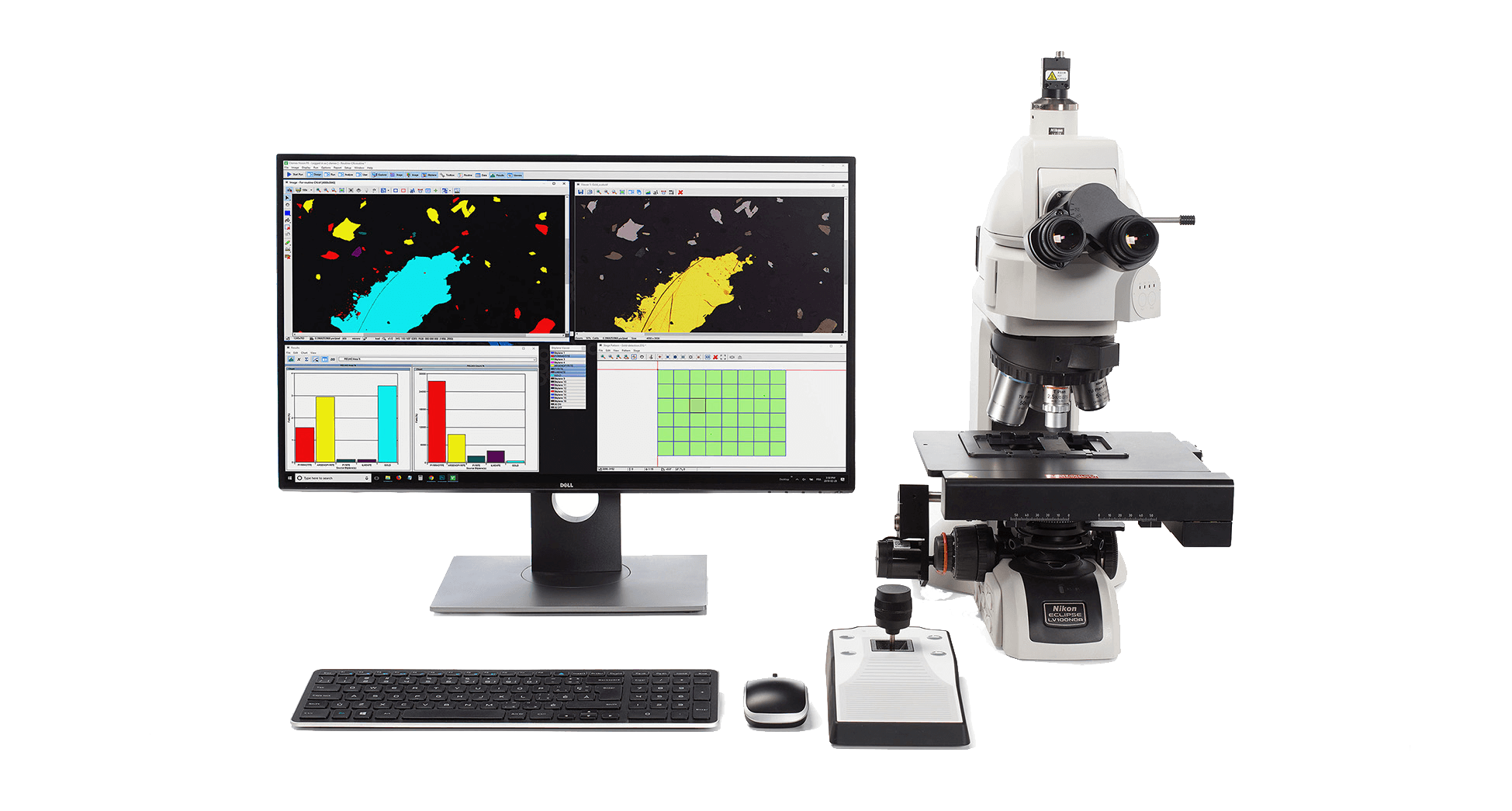

Figure 1. Image of austenitic stainless steel at 100X.

Figure 2. Grain boundary is segmented using the Austenitic algorithm prior to measurement.

CLEMEX SOLUTION FOR AUSTENITIC GRAINS

Reproducible detection and measurement of grain size as per ASTM E112 was performed using Clemex Vision image analysis software calibrated with a NIST-traceable stage micrometer.