Image Analysis for the

Automotive Industry

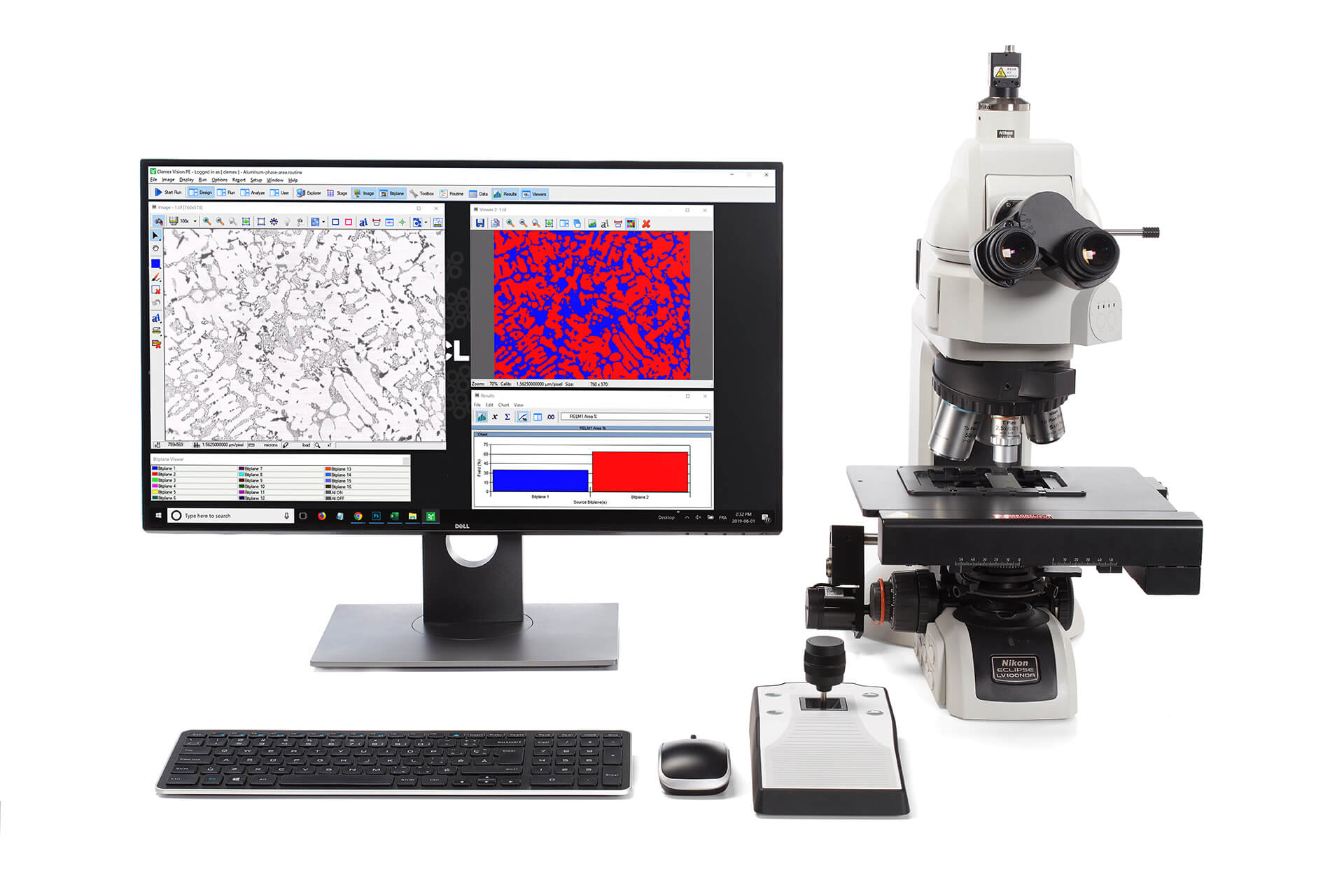

We provide automotive companies with testing solutions for hardness testing, contaminant analysis and quantitative metallography for a vast array of vehicle parts. Automate with us your microstructure analysis of incoming and outgoing materials to ensure critical components have the required physical properties for use in end products.

APPLICATIONS

Our image analysis software is exceptionally flexible, allowing for any number of distinct routines to be run on the same system. These routines come packaged as a library of existing applications or can be developed by our applications specialists.

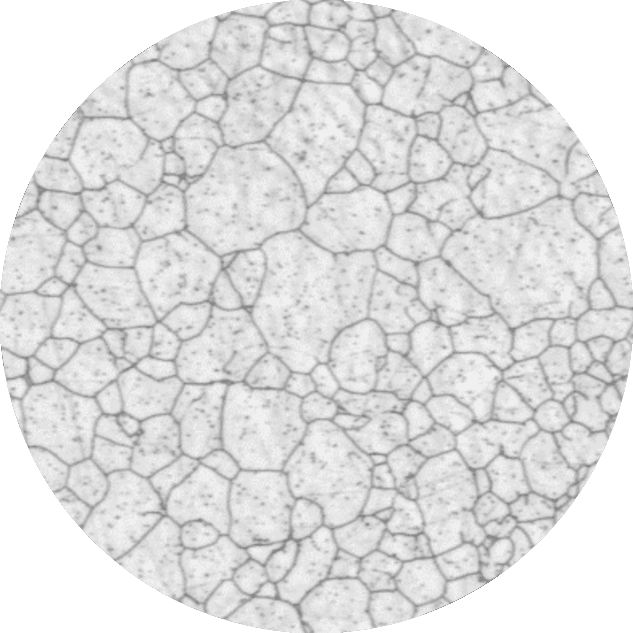

Grain Size measurements

- Intercept, grain size and boundaries in pure aluminum

- Grain size distribution in steel as per ASTM E112

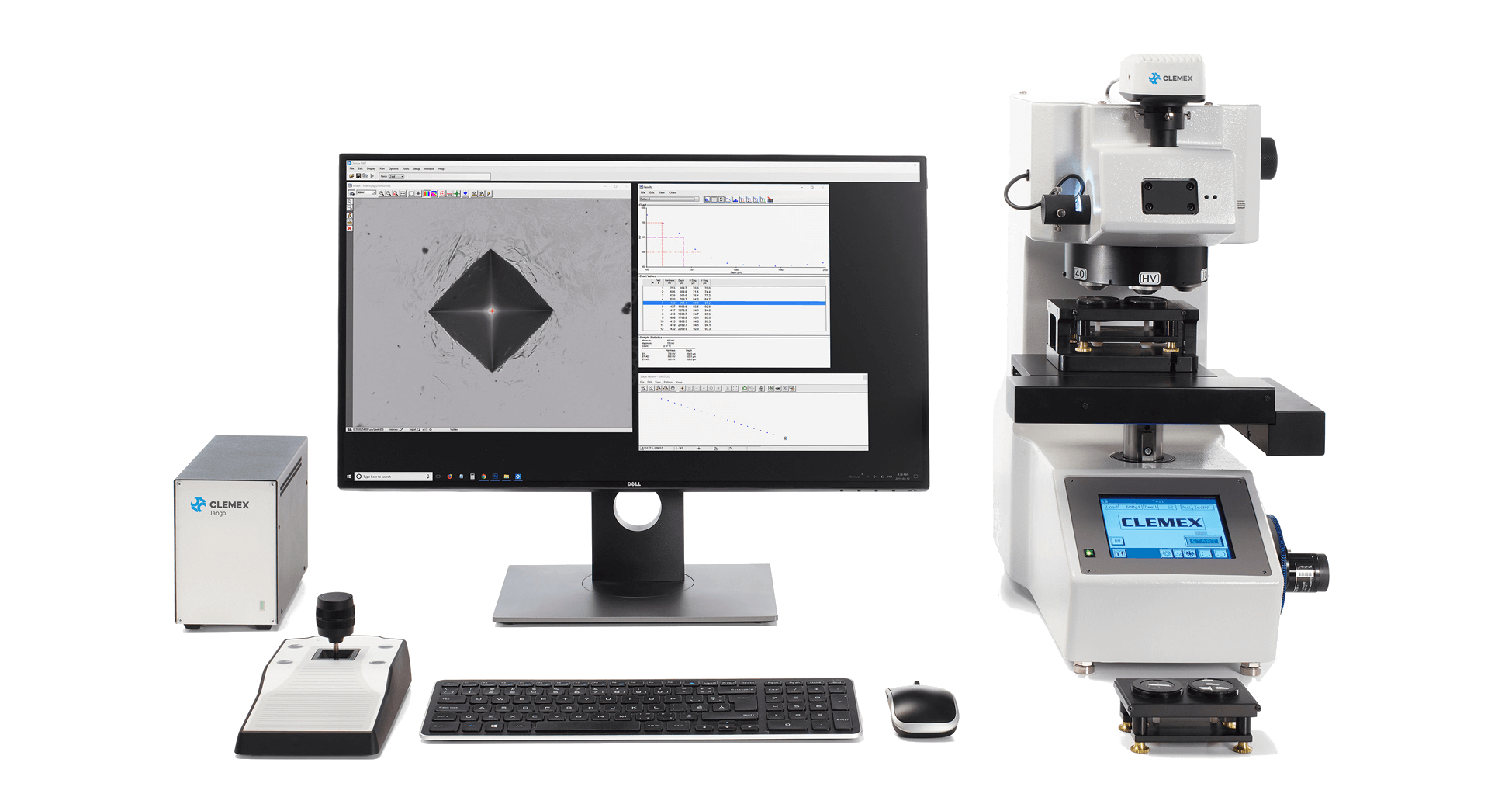

Hardness Testing on Weldings and Automotive parts

- Micro hardness testing of heat affected zones on weldings (ISO 6507)

- Hardness testing and delta ferrite percent on weldings

- Vickers hardness testing and grain size measurement on steel

- Grain size measurement by Heyn Intercepts Method and hardness of 416 stainless steel plate

- Nodularity and Vickers hardness of engine casting

Various Image Analysis on Automotive parts

- Cleanliness inspection according to ISO 16232 on filters

- Particulate contamination as per ISO 4406 – 4407

- Area percent, size, diameter and aspect ratio of black particles in fusion zones

- Manual measurements on seat tracks: Length, radius, angle, line and arc.

- Nodularity and ferrite pearlite evaluation as per ASTM A247

Direct contact with experts

Ms. Zschocke, laboratory manager at Neumayer Tekfor GmbH, has been an enthusiastic user of a hardness testing system from Clemex Technologies for over 5 years.