Microhardness testers are used by materials scientists to investigate various mechanical quantities of different samples. The primary method typically involves applying a loading force to the sample surface using a physical probe and measuring the resulting effects. This can help illuminate a wide range of mechanical phenomena including creep characteristics, dislocation nucleation, elastic modulus, fracture toughness, and – perhaps most importantly – hardness. However, there is no universal test method suitable for all microhardness measurements.

Knoop microhardness testing is an industry-standard technique for exploring the mechanical hardness of brittle materials or thin samples. It is one of several different test methods used to determine hardness via micro- and nanoindentation.

At Clemex, we pioneer innovation of indentation measurements for microhardness testing, leveraging our unique understanding of process automation and visual imaging to enhance a variety of different test methods, including Knoop microhardness.

Knoop Microhardness Testing: The Basics

Hardness is the quality of resisting plastic deformation, which encompasses abrasion, bending, cutting, penetration, and more. Though it has been variously defined throughout history, high hardness has always corresponded to greater deformation resistance. This has given rise to a wide range of test methods and indentation measurement types, from the Brinell scale to Vickers hardness.

Knoop microhardness testing was developed in the late 1930s by the US National Bureau of Standards as a method for determining the relative microhardness of brittle materials like ceramics and glass, or for thin sheets and organic coatings.

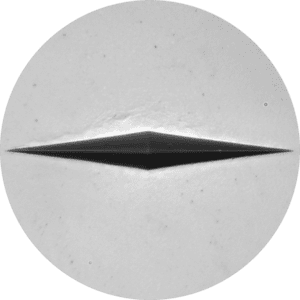

A typical Knoop microhardness test follows the standard indentation method, whereby an indenter tip is pressed into a substrate at a known load for pre-defined dwell times. The probe tip used in Knoop microhardness testing has a distinctive elongated pyramid shape with a length-to-width ratio of approximately 7:1. This is pressed into the surface at low indentation pressures of, typically, no greater than 1kg. By measuring the length of the elongated diamond impression using microscopy or in situ visual imaging, it is possible to calculate the Knoop hardness.

Knoop Microhardness Testing with Clemex

At Clemex, we strive to offer the widest possible range of test and measurement equipment for specific application areas. We offer a broad range of microhardness testers that are completely user-programmable and compatible with Knoop indenter probes. If you would like to speak with a sales representative about the best Knoop microhardness tester for your specific material or field of study, simply contact a member of the Clemex team today.