Microhardness testers are indispensable pieces of kit for materials scientists and process engineers around the world. They provide the means for investigating the various mechanical properties of myriad different material types, from creep deformation to viscoelasticity.

Although operators can explore a wealth of physical characteristics via microhardness testing, one of the most common objectives is investigating the localized hardness of engineered ceramics, metals, and polymers. This is carried out via indentation – which is a similarly diverse test method with standard versions including Brinell, Knoop, Rockwell, and Vickers hardness tests.

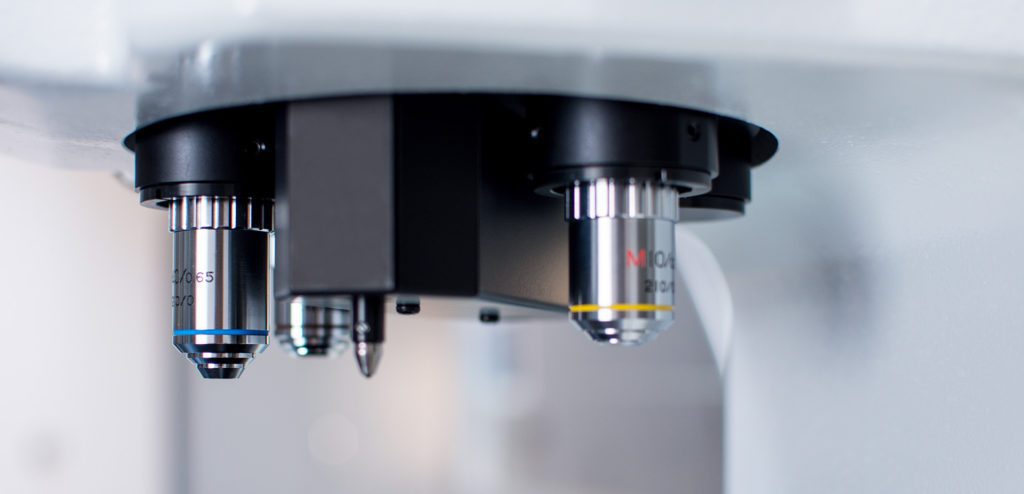

An easy way to differentiate between different microhardness testing methods is by the geometry of the indenter tip. Both Vickers and Knoop hardness test methods utilize a pyramidal indenter, for example, but Knoop indenters are elongated whereas Vickers microhardness testers use diamond tips with uniform length-to-width ratios.

So, how do you choose the right indenter tip and test method for your material? Here we will offer a direct comparison of Vickers and Knoop hardness testing to help you understand the difference.

When to Use Knoop Hardness Testing

Knoop microhardness testing follows the generic indentation principle to measure the resulting plastic deformation of sample substrates. Hardness is calculated by measuring the length of the impression as a function of the applied load and dwell time. It was specifically designed to resolve issues with indentation testing of brittle materials and thin substrates and is now widely employed for evaluating the hardness of thin coatings. We explored Knoop testing in our recent article: What is Knoop Microhardness Testing?

When to Use Vickers Microhardness Testing

Vickers hardness testing likewise follows the standard indentation protocol, but hardness is calculated by measuring the diagonal lengths of the indent. It was introduced in the early 20th Century as an alternative to the pre-existing Brinell scale for testing the hardness of different materials – primarily metals. Vickers microhardness testing is now an industry-standard due to its ease and versatility. Engineers largely rely on Vickers indentation when testing bulk material hardness, as well as various dynamic properties such as scratch testing of films and foils.

In summary, it is typically best to use the Vickers microhardness test method unless your material of interest is particularly brittle. A Knoop indenter will help overcome sample cracking during the test, enabling you to assess the hardness of extremely thin layers on the micro range.

Microhardness Testers from Clemex

At Clemex, we design and supply a range of turnkey microhardness testers with flexible automation and magnification options for real-time imaging of sample deformation. With easy transference of the probe tip, each of our systems can be employed for high-precision Vickers and Knoop hardness testing.

If you would like more information, simply contact a member of the Clemex team today.